Some mini quad motors are labelled CW and CCW, and it can cause a hell of a confusion for a lot of people in this hobby including experienced quadcopter builders. In this guide we hope to answer some of the questions with easy to understand diagrams.

Update (Jan 2019): Motors used to have CW and CCW threaded shafts for mounting the props, but this is back in the days. New motors on the market does not have this distinction anymore, they all have the same thread direction, and you can disregard this article.

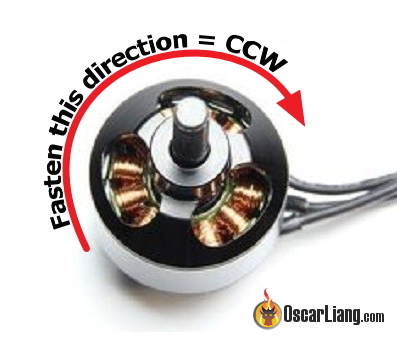

Basically CW (clockwise) and CCW (counter clockwise) motors are still the same motors, apart from the prop shaft threads which have opposite direction. That means for a CCW motor, the prop nut is secured by turning clockwise. And for CW motors, the prop nuts needs to be rotated anti-clockwise in order to fasten.

Some motors only supply standard direction thread, which is CCW; While some motors comes in pair of both directions, or you might be given a choice to choose which rotation you want when purchasing.

Prop nuts of different directions usually comes in different colour, such as black and silver for better user-friendliness.

Advantages of having different CW and CCW threads

So why having 2 different shaft threads and making it so confusing?

They call this ‘Self locking’, because on a quadcopter we have 2 motors spinning clockwise direction and the other two spinning counter clockwise. By using threads that are the opposite to motor spin direction, the prop nuts automatically lock themselves down and won’t come loose.

However it becomes difficult to source spare prop nuts for both threads. And it also makes it confusing to which way we should turn to remove the prop nuts when changing propellers.

Prop nuts are basically M5 nylon nuts. In hardware stores, they are refereed to as right handed and left handed thread as opposed to CW and CCW.

Identify CW and CCW Threads

So basically if you can fasten the prop nut clockwise, then you have a CCW motor, for which you should get the Right handed thread nut (standard thread).

For CW motors, go for the Left hand thread nuts (reverse thread)

Where to install CW and CCW motors in a quadcopter?

To enjoy the benefits of CW and CCW motors, you should install them correctly, otherwise they will have the opposite effect.

Rule of thumb: Motor direction should be opposite to propeller spin direction.

For example, CCW motors should be installed on CW propeller rotation, follow this diagram.

And the left / right hand thread follows the right hand rule.

42 comments

What’s the pitch on the nut threads?

The article is correct, for QUADS. It’s been my experience that fixed wing use the opposite terms because the point of view (POV) for the direction of spin for the props is the opposite. The POV used for fixed wings are from the pilot’s or cockpit POV. So a CW (Normal) spin of the prop/motor uses a CW or right-hand nut as seen from the cockpit. But the POV for a quad is from the top. So a CW spin of the prop/motor uses a CCW or left-hand nut, if you want a self-tightening nut, which is desirable. If you don’t use a self-tightening nut, you would want to use a cotter pin and hole to keep the nut on.

Hi Oscar,

your picture and the description of threads is still wrong IMHO. You write:

“For CW motors, go for the Left hand thread nuts (reverse thread)”

That is demonstrably wrong, a CW motor TIGHTENS the nut clock-wise, ergo it is a right-hand (standard) thread.

See this motor: hobbyking.com/en_us/multistar-viking-brushless-outrunner-drone-racing-motor-1808-2600kv-ccw.html

You can clearly see the tready being left-hand, as defined by your own “right hand rule” diagram on the bottom.

Your title picture should read: “Fasten this direction -> CCW prop” – remember, standard thread means righty-tighty

Your quad prop-spin vs. prop nut diagram is correct, which makes your whole article confusing as hell.

Your “Identify […] threads” chapter should read: “if you can fasten the prop nut CLOCKWISE, then you have a CW motor, for which you should get the Right handed thread nut (standard thread). For CCW motors, go for the Left hand thread nuts (reverse thread)”

And mabe you should mention that the indication CW for a motor does NOT define rotation direction.

Take an example here: frankschrader.us/multicopter-drone-propellers-and-motors-meaning-of-cw-and-ccw/

One picture and all was clear to me.

Sorry and

Best regards,

Majo

What NUM Nuts came up with the “label” system that has the smallest chance of Screwing up things?

What would be wrong with “normal” and “reversed” threaded

normal threaded shaft has a normal threaded nut etc.

SQUIRRELS would even understand that.

I normally buy RDQ motors that don’t distinguish between CW and CCW. The prop nuts fasten buy turning clockwise. So from reading this article, I thought they were CCW. Because it states “CCW motor, the prop nut is secured by turning clockwise” So I went to buy some CCW Emax motors, wanting them to be compatible with the ton of prop nuts I have laying around. and the threads are opposite, you turn them counterclockwise to tighten. I am so confused.

Hi Oscar, i burned a Racerstar BR2205 2500kv labeled CCW. I have one spare same motor but it is CW instead of CCW.

Can i replace the dead CCW with the spare CW? In your article i read that just prop shaft threads are different but motors are the same. I’ll only check direction in BLHeli Configurator to be the right one.

Makes sense?

Thanks

Roberto

Yes of course :)

The only difference is you fastening the nuts the other way :)

And yea, you can change motor spin direction in BLHeli :) Easy :)

Hi Oscar,

I remember I read somewhere in your page you use the 4 motors of same type, all ccw I guess, so how do you make sure you wont have loosen nut in the motor which are spinning CW ?

Sorry If my question is too simple, but I am very beginner so this question struggles me haha

Greetings !

use proper lock nuts, and fasten them properly you should be fine :)

So, to summarize:

With BF standard motors rotation:

Motor 1 need to be labeled CCW

Motor 2 need to be labeled CW

Motor 3 need to be labeled CW

Motor 4 need to be labeled CCW

With BF reversed motors rotation:

Motor 1 need to be labeled CW

Motor 2 need to be labeled CCW

Motor 3 need to be labeled CCW

Motor 4 need to be labeled CW

I’m right ??

Hi, Would you comment on this. How is the nut suppose to stay on when the Nut is removed CCW but 2 motors spin CCW? I have a race quad that CCW removes the nut. 2 motors spin correct direction ( to tighten the nut) but the other 2 spin in the direction to remove the nut. Basically all 4 motors have the same nut direction the same.

They are nylon lock nuts.

I just want to say:

NEVER buy ccw motor with a M6 shaft.

It will be practically impossible to get spare part.

I tried mailing Racestar to get some same part, but they would only sell me 100s. And they couldnt tell me of any reseller.

M5 seems to be easier but still you cant just go to your nearest supplier.

Dang, just shoot me, have not flown my QAV 400 in over a year or so, the mini’s have been keeping me busy, and forgot I had changed out the CW motors to reverse threads, just broke one trying to get the nut off. Live and learn, but on the bright side after looking at the t-motor site for my mt2216-9 v2 kv1100 motors I see I can get short threads to run my left over phantom v1 and v2 props.

OMG! ive been in RC model hobbies for almost 2 decades now, the last decade or so being mostly about flying. for the last 4 or 5 years the hobby has focussed itsself around multicopters. at first just consumer ready “off the self” quads but the last few years have been about completely scratchbuilt multirotors, and these days progressed into carbon fiber FPV race drones. I have probably built about a dozen multicopters using brushless motors. untill earlier this week, when a friend who had removed all four prop adapters and forgot which one goes where so he asked me for help, i had never really stopped to think about this matter. trying to advise my friend i initially told him what i always do: spin the motor off the esc, if any motor is not spinning “inwards” while viewing the quad from either the front (for the front 2 motors) or the back side (for the rear 2 motors, swap 2 wires. when motor directions are correct, the nut should be automatically tightened. best way to check that is by holding the nut in place and hand-turn the bell in its appropriate direction. this should pull the nut down the shaft, not up. my friend replied: that makes no sense because that means all the motors are running the wrong way. now, I was getting confused LOL. a lot of motors these days have a seperate prop adapter and i have a number of them in currently used models. however, i never really paid attention to the CW/CCW markings on the bell of the motor, since i never needed to know which was which because of the method i just described. so in order to be sure i was giving my friend the correct info i checked one of the motors that has a fixed propshaft and to my amazement it had right handed “normal” thread on a motor marked as CW. really confused about this i checked my models with prop adaptor pieces only to get more confused because it turns out i have about half of my CW motors in a CCW position on the quad. whats even stranger is that i also found a number of left handed “reversed” thread adaptors on CW indicated motors. finally i grabed a new and unopened multistar elite 2204 motor to find the CW motor has CW thread (righty tighty). meaning it did in fact not make any sense because spinning the CW motor in a CW direction wouldbof course UNTIGHTEN the nut?!?. reading your article and seeing that picture made me realise that for all this time, i never knew that the direction indicated on the motor is susposef to be viewed from the backside (bottomside) of the motor. Being a designer/engineer in the machine building industry by profession, hearing of such an outrageous, illogical, contradicting, confusing, unusual, backwards interpretation of a motor direction indication, has literally caused me to drop my yaw and just frown for a minute. not to mention how this goes against basically every form of any internationally standardized technical definitions, as well as any regional standards that i have come arcoss all over the world. As far as i know, an electrical motor, be it a 40MW three phase motor or a 6x16mm coreless 50k rpm motor, in all the common tech standards like ISO, DIN, AISI, ASTM, JST, etc, the motor direction is indicated by an arrow revolving around the center axis, which is viewed from the FRONT of the motor. i say front, for practical understanding but in a technical datasheet you will either see an additional drawing of the motor indicating what the “front” side is, but more commonly one speaks not of the “front” but of the much more clearly identifiable: “motor shaft orientation”. and for good reason because in most fields, a “direct drive” situation (like a prop on an outrunner) is considered somewhat uncommon when compared to a traditional motor-gearbox assembly, in which most people would intuitively identify the front/back/top/bottom of a “motor” by the way it is positioned on its mounting features and the gearbox’s output drive axis.

but enough about that. my point is: first of all, how did we end up with such a wack system to indicate direction for these little brushless motors? secondly, why do they even indicate a CW or CCW marking on the bell of a “bidirectional motor”(*) when it is designed to be fitted with a seperate, interchangeable L/R adapter. and third: (*) are they truly bi-directional in terms of timing and physical symmetry of the internal components or is there an optimized turning direction due to, for example, the direction and configuration of the spool windings?? And lastly, if the previous question is so, then why are we always randomly soldering motors to ESC’s, building a power distribution circuit, completing a setup to controll the signal output channels, and running a quick test to find out that all your motors need to have some wires resoldered to correct the direction. all of which is done in a half un-isolated open wiring test situation. what is so hard about just color coding, number marking, symbols, icons, abbreviations, text marking, etc the motor wires according to their corresponding spools on the stator, so that an end-user can connect them correctly at all times?!?

alright, my apologies to anyone that has taken the time to read all that… what started as a comment about how amazed i was about never knowing what the deal is with outrunner motor directions and prop shaft thread, somehow turned into me ranting about how messed up that is and ended in a bunch more questions and confusion…

ill leave it at that,

rock on people!

Thomas H

Mike,

CW refers to the thread of the motor shaft, not the direction it spins. That is why the propeller has to spin in an opposite way to the thread direction.

If your motor is not threaded and the propeller just pops in, then propeller should follow the way the motor spins.

Cheers

I really tried to remove all doubt for those getting into this where you have actually search the web due to instructions being so terrible.

http://tinyurl.com/jca3a2r

It is an image loaded to facebook.

This industry needs a customer service overhaul.

you have a very nice image there, i think i will make a similar one to help explain it better

Or more practical (directly to the source of the reason): if your motor is spinning (slowly, no prop and no nut) and you hold the matching nut against it it should yank in the nut and tighten it.

As a result this means that CW motors, which have right-handed threads (and match the blank nuts) spin CW as seen from the rear (right handed is tightning something when you are behind it, at the side of thing you rotate CW with your right hand), but obviously spins CCW as seen from the front. Therefore, to do ourselves a favour, we should also talk about CW propellers for propellers that need to rotate clock wise as seen from the BACK (so you get all the air blown into your face, unless it’s a pushing propeller of course; but in all cases you are on side of the motor). The only thing left to remember then is that for some reason the community likes to draw images of drones from the top – which then reverses CW and CCW – the source of all confusion.

Carlo,

I’m not sure if i understand your way of explaining a tightening revolution correctly but i do know this:

all standard fastening material (like a nut or a threaded shaft) is normally tightened by applying a clockwise rotation. so considering that any normal person would view a clock from the front (the display side) one will identify the direction of the motion of the clock’s hands as right turning, when taking the top of the circle (12 o clock) as a starting reference. however, when applying this right turn revolving motion to a fastener, the operator is now executing the actuation away from him. (basically, are mimicking what we observed on something facing us (the clock) but we are executing it onto something else in that same observed way, right turning, only we do it while we are viewing ourselves “behind” our hands.

bottomline is: if a motor is indicated by means of a term that refers to a clock, which is ALWAYS viewed from the front and the motor axis points TOWARDS you, to my opinion the confusion here is mostly due to the fact that they then apply the clock’s definition of direction to the backside of another product. or maybe its better put as: they have taken the “beholder’s” perception of direction and applied it as seen from the object’s own point of view. (you would be speaking as if “we are now the motor”)

Hi oscar,

I could never get this right so I just use a die set and make all my motors shafts CW and use plain self locking nuts. Never had a nut come off.

same here :)

Hi Oscar

Thanks for reading, and thanks for clearing up the propeller direction naming.

The phenomenon of self-locking is way beyond the scope of this discussion. But, it has nothing to do with drag or inertia.

THE TRUTH IS OUT THERE. But you have to want it.

So Oscar, why are the wires connected to a positive voltage source usually red????

Thanks

RM

Hi Oscar

I must comment on what was written in red about prop direction. If the motor direction is evaluated from the rear, behind the motor, which is correct; and the prop direction is evaluated from the same point of view as the motor, behind the motor and behind the prop, which is correct, they will both be turning in the same direction!

If you look at the motor from the rear, and the prop from the “front” (which is not according to convention) you will end up labeling them as turning in opposite directions.

HOWEVER, your diagram seems to follow some thinking in the quadcopter community. The diagram works if you apply the following rules (“conventions”):

1) the alphabetic letters CW and CCW refer to the direction of the motor (viewed from the rear).

2) the purple circles/arrows refer to the direction of the props viewed from in front of the props (that is, looking down at the paper).

Given these definitions, the diagram is consistent, and useful.

But the correct description of the rotation of a prop is not determined from the point of view in front of it.

The purpose of my initial lengthy response (the substance of which does not originate with me) was to get us on the same page speaking the same language.

Thank you for maintaining this forum.

Sincerely,

RM

HI Randy

Yes, this is totally following the quadcopter community thinking :)

And this is how they are described when you shop for replacement parts.

thanks

Oscar

Oscar, with all respect, your statement is wrong. Here is why. I have EMAX MT2216 on my quad and initially (due to stupidity) had prop adapters installed in the way you explained – left-threaded on CCW and right-threaded on CW. As a result, I struggle to count the numbef of nuts I lost. One got loosen in air that lead to a crash and broken arms. After I researched closely and corrected mistake, all became well.

So, easy way to understand – put your nut on thread (losen, not tighten!), then hold it still by your fingers and then rotate MOTOR itself in desired direction – and you’ll see where the nut goes.

So, the right way:

CCW Motor = right-handed thread;

CW Motor = left-handed thread.

* all stated above assuming you determine thread by ‘tighten’ direction and looking at the motor from the top, where propeller attaches.

BR//Roman.

Hi Oscar,

here is an addition to be more clear:

– Why do we need to hold the nut rather than motor?

– That is because by this we simulate the forces affecting the propeller and nut. Since we normally use pulling props, there are two main forces that affect the whole process:

1. Drag – props are tending to rotate slower than motor – (surprise! they’re curved! :) ).

2. Traction – propellers are tending to come out from thread and being held by nut.

When you flying actively and abruptly change motor’s RPM, due to inertia props can’t change their speed right away, they “stall” for a moment and ‘adhere’ to a nut, and if nuts have thread matching the rotation direction (like CCW motor with right-handed thread on prop adapter) they’re easily come off with propellers. In other case they’ll tighten.

BR//Roman

In the last sentence (“like CCW motor with right-handed thread on prop adapter”) I meant CW, off course! Sorry for confusion, that’s typo.

Thanks for the info, detail why and what self tightening is, is beyond the scope of this post :) but thanks anyway :)

Roman, with all respect, you don’t get what i meant in the post :)

when I say right handed or left handed in the post i was referring to the nuts.

CCW motor uses left handed nuts and CW motor uses right handed nuts.

That’s all you need to know when buying replacement nuts on ebay :) don’t worry about the threads.

HI Oscar Good article, although now I’m even more confused :) My experience is totally oposite i.e. for CW motor I’m using left handed nut.

1. Imagine your rotor rotating CW and put some obstacle for propeller: in my setup it will lead to fasten the nut (if wind is considered as a obstacle so that’s what we need, right?)

2. Imagine start of the rotor to CW direction: According to law of inertia the propeller has a tendency to stay in original position, in other words it tries to rotate CCW: in my setup according to friction it will lead to fasten the nut.

But my problem is that I can’t feel Mechanical Preccesion so far (that’s how I learn physics – I imagine I’m a nut and I try to feel the forces). Here is similiar explanation why bike pedals are fasten in a direction which doesn’t make a sens for the first time: http://blog.everydayscientist.com/?p=2655

Hi Frik

tell me, have you ever bought any motors that are do one version (only one type of prop shaft, no CW or CCW difference)… what prop nuts do you use for those? and are these motor CW or CCW?

like the other guys commented above, it’s all about conventions, what people use. Just like RP-SMA and SMA which the difference has nothing to do with polarization. These things can be different from industry to industry, from hobby to hobby.

Hi Oscar

actually I build my first drone a few days ago, so here comes my “experience” from :)

I never used any other motors before and I didn’t talk to RC guys yet to get their experience.

My flight time is cca 40 minutes with CW motor and CCW fasten nut and the nut is still perfectly tighten. Probably it’s just matter of luck. Actually if propeller hit obstacle, like a tree, it would be better it will lead to loosen the nut rather than broke the propeller.

So I’m gonna to change my motor-nut setup as your article recommends.

Thanks.

Greetings

When I read in the article “so which is CW and which is CCW…the nuts are not categorized as CW or CCW, but rather right handed and left handed” I felt in familiar company, having wondered about this for years. I decided to research this, which took an embarrassing number of hours. What I came up with is summarized below.

The use of terms about handedness, translation, and rotation do not reveal deep laws of physics, but are conventions, words that are assigned to actions, objects, direction, etc. Some conventions are simple: when an apple is dropped, its direction of movement is down. Don’t know why the word “down” was used, and it doesn’t reveal secrets of the universe, but now we can discuss the falling of an apple because we have chosen a word to use.

Some objects and actions require a lot more details be described about the situation before we can even begin to have a discussion about it. Such is the case with direction of rotation, handedness (chirality), what the right hand rule means and how things must be set up so the right hand rule applies.

Threads and Handedness

A screw thread is a helical structure used to convert between rotational and linear movement or force. The nut rotates and moves linearly along the threads. A screw thread is a ridge wrapped around a cylinder in the form of a helix (thanks Wiki.) Fancy words for a familiar object. The helix of a thread can twist in one of two possible directions. These two directions have a special symmetry known as handedness or chirality (from the greek chiros, or hand.) Our hands are the most common example of this symmetry, leading to the name. [Remember, all of these words are just conventions precisely describing an object so we can communicate about it.] NOW we come to a convention that more directly applies. The threads are oriented so that the threaded item, when seen from a point of view on the axis through the center of the helix, moves AWAY from the viewer when it is turned in a CLOCKWISE direction, and moves toward the viewer when it is turned counterclockwise (again much help from Wiki.) This is assigned the name of a “RIGHT-HANDED” thread, since the objects and motion can be described using the right hand. It should be noted that when using the diagram the head of the bolt would be on the “thumb end” of the vector gripped by the curling fingers showing clockwise rotation of the screw. Remember, this is being viewed from the bottom end of the diagram, so clockwise rotation of the nut carries it away from the viewer and toward the head, eventually resulting in tightening of the nut.

On a RIGHT-HAND thread, turning the nut CLOCKWISE, leads to TIGHTENING.

This really is all there is to it. A collection of fairly simple definitions. It is confusing to us because we have never been presented with all the conventions at once.

The helical threads can twist in one other possible direction. Following the same series of definitions results in:

On a LEFT-HAND thread, turning the nut COUNTERCLOCKWISE, leads to TIGHTENING.

Now we have enough information to address the question at the beginning of this comment.

PROP NUTS – “…so which one is CW and which is CCW?…and they are not categorized as CW or CCW, but rather right handed and left handed.”

We have developed the relationship between rotation and handedness. Best guess here is that one terminology became more popular than the other. A clockwise nut is always right handed, and a counterclockwise nut is always left handed. One term not yet mentioned is gender. A shaft with external threads is referred to as male. A nut has internal threads, referred to as female. But this doesn’t change the fact that a right handed (CW) nut always matches a shaft with right handed (CW) threads.

So why does it matter? Why should we use right handed hardware on a shaft driving a load in a clockwise direction, and left handed hardware on a shaft driving a load in a counterclockwise direction? It’s not due to torque or inertia, but due to a phenomenon called MECHANICAL PRECESSION. This is a subject for another day.

If you have made it this far, thanks for reading. This is what it took for the terms to make sense to me. Comments are most welcome.

Best wishes

RM

LOL, thanks for the comment, this is probably the first time I have someone’s comment longer than my original post!

So if i am reading it correctly, I think your research agrees with what i have explained?

I wasn’t trying to go into too much detail why CW are CW and CCW are CCW… I was only trying help others identify which is which, and what prop nuts they should get for those motors…

Is it possible to get such propeller shafts for DYS BE1806 somewhere?

i am not sure, usually these CW/CCW versions are built-in prop shafts.

Ted

I have wondered a lot about this also. The best (only) discussion I have seen is at Wikipedia’s entry “Precession (mechanical)” for an excellent diagram, in motion of course.

“question everything”

Best wishes,

RM

Dear Mr. Liang, I am new at building quadcopters and your blog has been an amazing help to me and I thank you for that. Keep up the good work.

That being said, I think you may have the CW, CWW prop nut thing mixed up. If I fasten the nut in a CW direction, and the motor turns CW, it will spin the nut off. Please correct me if I’m wrong.

Sincerely,

Ted White

Hi Ted, thanks for the comment. I think I haven’t made it clear enough. In this article, when saying CW/CWW I was only referring to motors (prop shaft thread).

This sentence in article: “So basically, if you can fasten the prop nuts clockwise, then you have a CW motor or prop shaft.”

I change my motor-nut setup according to this sentence and during 1 minute of hovering 2 nuts drop to the earth. Maybe I also understood terms in this article wrong :)

Sometimes it’s better to make a video like this one: youtube.com/watch?v=yZNpo7BTxrI

So for motor rotating in CW direction you have to fasten the nut in CCW direction and viceversa.

Hi Fric

So for motor rotating in CW direction you have to fasten the nut in CCW direction and viceversa.

THANK YOU Frik, that’s what we all wanted to know. Simple as that. Glad I read the whole blog, or I would still be in the dark.