In FPV drones, the electrical wiring and connectors play a crucial role in ensuring that the drone operates efficiently and safely. In this tutorial, we will cover everything you need to know about electrical wires and connectors, including the different types and how the size of wire and connector affects performance.

Table of Contents

What Type of Electrical Wires Should You Use for Your FPV Drone?

There are several types of wires available, the most common type used in FPV drones is silicone stranded wire. Compared to solid core wires, stranded wires are more flexible and easier to work with.

Compared to PVC-insulated wires, Silicone-insulated wire is preferred for RC applications due to its flexibility, especially as multirotor frames and components continue to shrink in size. Silicone wires are also lightweight and can tolerate a wider temperature range, making them more durable in extreme environments. In addition, they are less likely to melt or shrink when exposed to heat during soldering.

Electrical Resistance in Wires

One important factor to consider when choosing wires for your FPV drone is the wire’s resistance. Longer or thinner wires will have more resistance, which can lead to voltage drop and power loss (especially so for the battery). This is why wires have a current rating.

To minimize resistance, it’s best to keep your wires as short as possible. While thicker wires can also help reduce resistance, they can add weight to your drone.

To ensure that your power system can deliver the required power, make sure your wires are appropriately sized for the components in your drone. Choosing the right size wire will prevent it from becoming a bottleneck in your power system and allow your drone to perform at its best.

Understanding Wire Gauge

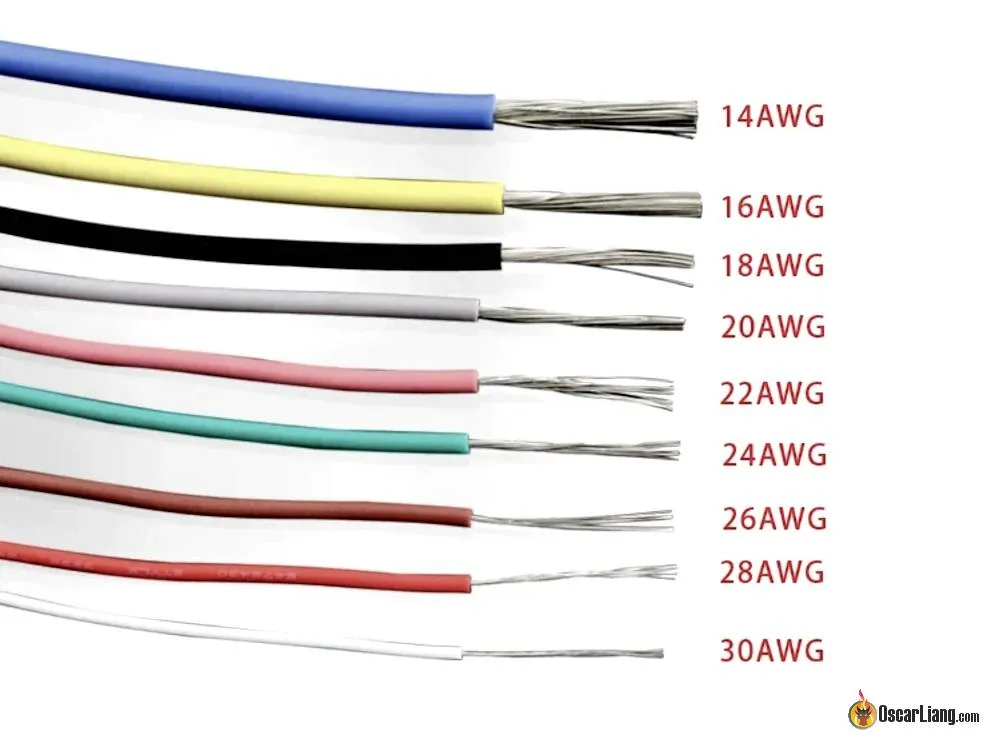

Wire gauge refers to the thickness of the electrical wire and is measured in AWG (American Wire Gauge). Choosing the right wire gauge is important to ensure that the wire can handle the current required by the component it is connected to.

In general, the higher the AWG number, the thinner the wire. The lower the AWG number, the bigger the cable size and current capacity. The current rating of a wire is the maximum amount of current that it can safely handle without overheating or becoming damaged.

When building an FPV drone, minimizing weight is important. For instance, here are some commonly used wire gauges for different components on a 6S 5-inch FPV drone:

- 14AWG for Battery XT60 Pigtail

- 18AWG-20AWG for ESC and Motor power wires

- 28AWG for other low power components and signals

When connecting two wires, the maximum current that can be passed through them is limited by the smaller wire. Therefore, if you are extending a wire, it’s best to match the wire gauge and use the same AWG wire. Using larger wires than necessary doesn’t provide any benefit but extra weight, which is not ideal for an aircraft.

Here’s the estimated weight per meter of wire for different AWG number:

- 24 AWG – 4.5g

- 20 AWG – 7.5g

- 18 AWG – 11g

- 16 AWG – 20g

- 14 AWG – 27g

- 12 AWG – 39g

- 10 AWG – 61g

Disclaimer: The numbers in this post are a guide only.

Current Rating Look-Up Table

To determine what AWG wires you need, you should first work out your quad’s maximum amp draw and then refer to a current rating look-up table. The current rating is normally a continuous current if not specified.

Different electrical wire manufacturers may have different standards and current ratings. Here’s one example:

As a general guideline, I personally follow this table based on the burst current requirement (e.g. current draw at full throttle):

- 10AWG Wire: 250A

- 12AWG Wire: 160A

- 14AWG Wire: 110A

- 16AWG Wire: 80A

- 18AWG Wire: 50A

- 20AWG Wire: 30A

- 22AWG Wire: 24A

- 24AWG Wire: 20A

It’s important to use the appropriate wire size to minimize voltage drop and power loss due to resistance, and to reduce the risk of overheating. However, in some cases, it may be acceptable to use slightly thinner wires if the wire length is short and the current bursts are only for a short period of time to minimize weight.

In my 6S 5″ builds, I usually use 14 AWG wires for connecting the battery, even though the maximum current draw might be slightly over the current rating of the 14AWG wire. I don’t think this would be a problem because, firstly the wires are quite short; secondly, the current bursts typically only lasts for a couple of seconds, even if you leave it at full throttle for longer, the battery wouldn’t be able to keep up anyway. The main reason I prefer 14AWG over 12AWG is because they are easier to solder to the ESC, and can shave a couple of grams off my build.

There’s also voltage rating for electrical wires, but it’s usually not a concern for RC applications, since the voltage we are dealing with are well below 30V. The wires we use can tolerate much higher voltage (e.g. hundreds of volts or even higher).

Where to Buy Silicon Electrical Wires

Are Red and Black Wires Different?

No, red and black wires are the same wires, just different in colour. You can use any colour wire you want for your drone, but conventionally, red is used for positive power and black is used for ground. Following this convention makes it easier to visualize which wire is which and helps prevent mistakes. There are other colour-coded wires which are typically for signals, but it’s totally up to you what color wires to use.

12 AWG

Applications: For XT60 pigtail, high power 5″, 6″, 7″ FPV Drone.

- AliExpress: https://s.click.aliexpress.com/e/_DlSpVMh

- Amazon: https://amzn.to/3JcFN5H

- Banggood: http://bit.ly/2ALByxa

- GetFPV: https://oscarliang.com/product-bt0a

- RDQ: https://oscarliang.com/product-wj65

14 AWG

Application: for XT60 pigtail, medium power 5″ FPV Drone.

- AliExpress: https://s.click.aliexpress.com/e/_DEWmXTR

- Amazon: https://amzn.to/3JvxFi1

- Banggood: http://bit.ly/2ALByxa

- GetFPV: GetFPV

- RDQ: https://oscarliang.com/product-wj65

16 AWG

Application: for XT30 and XT60 pigtail, long range builds (80A burst).

- AliExpress: https://s.click.aliexpress.com/e/_DFtzaZX

- Amazon: https://amzn.to/3Jfu0DE

- Banggood: http://bit.ly/2ALByxa

- GetFPV: https://oscarliang.com/product-z3it

- RDQ: https://oscarliang.com/product-wj65

20 AWG

Application: for XT30 on sub250 builds, and motor wire extension for 5″ builds. 18AWG also works well if you don’t mind the slight extra weight.

- AliExpress: https://s.click.aliexpress.com/e/_Dk5DjAZ

- Amazon: https://amzn.to/3UoSSOH

- Banggood: http://bit.ly/2ALByxa

- GetFPV: https://oscarliang.com/product-jc8f

- RDQ: https://oscarliang.com/product-wj65

26AWG-28AWG

Application: for signals, power for your FPV system, receiver etc, basically anything that isn’t battery or motor related.

- AliExpress: https://s.click.aliexpress.com/e/_Deft3NF

- Amazon: https://bit.ly/3LkxHuE

- Banggood: http://bit.ly/2ALByxa

- GetFPV: https://oscarliang.com/product-qzda

Choosing the Right Connectors for Your FPV Drone

Connectors are an essential component for attaching two components temporally, such as the battery and ESC. You can also use connectors if you don’t like soldering.

For signals, it’s less of a problem and you can use any connector you want. However, when it comes to battery or any high current applications, it’s crucial to choose the right type of connector, because like wires, connectors also have a current limitation.

Here is a general guideline for the continuous and burst current ratings of some commonly used connectors:

- JST connector: 5A (10A)

- 2mm bullet connectors: 20A (40A)

- XT30: 30A (60A)

- XT60: 60A (180A)

While it’s tempting to overcompensate and use larger connectors, it’s not always necessary and can add unnecessary weight to your drone. In some cases, it may even have a negative impact on your drone’s performance. For example, when it comes to micro drones such as Tiny Whoops, there’s a debate about whether XT30 connectors or BT2.0 / A30 connectors are the better option. While XT30 connectors have a lower resistance than PH2.0, BT2.0 and A30, but the benefits are hardly noticeable while it’s much heavier, some argue that BT2.0 and A30 are the optimal choices because they provide a good compromise between weight and performance. You can learn more about these connectors for micro drones in my testing: https://oscarliang.com/micro-battery-connectors-testing/

By choosing the appropriate connector based on your drone’s specific needs, you can ensure that your drone operates safely and efficiently.

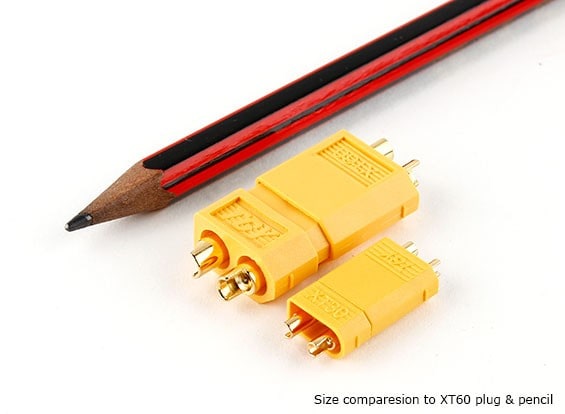

Where to Buy LiPo Battery Connectors

Two of the most popular battery connectors used in FPV drones are the XT60 and XT30 connectors. These connectors share the same design but come in different sizes and are rated for different maximum currents. According to the official datasheet, the XT60 connector is rated for a maximum current of 60 amps, while the XT30 connector is rated for a maximum current of 30 amps. These ratings are designed to ensure safe operation of the connectors under specific conditions.

However, recent test has shown that the XT30 connector can actually support a much higher continuous current of up to 60 amps without any problems, as long as the wires connected to it are large enough. This means that you can safely use an XT30 connector for applications that require higher currents, as long as you follow the appropriate safety precautions.

On the other hand, the XT60 connector has also been put to the test, and it has been found that it can safely handle burst currents of up to 180 amps for 10 seconds without any problems. This makes it a reliable choice for a typical FPV drones without the need to upgrade to heavier and bulkier connectors.

XT60 Connectors

- RDQ: https://oscarliang.com/product-xzn1

- GetFPV: https://oscarliang.com/product-hwx7

- Amazon: https://amzn.to/3l6oonc

- Banggood: http://bit.ly/2AuxHnC

- AliExpress: https://s.click.aliexpress.com/e/_Ddy57H7

XT60 14AWG Pigtail

Comes with wires soldered on.

- AliExpress: https://s.click.aliexpress.com/e/_DdHrwIp

- Amazon: https://amzn.to/403AkVQ

- Banggood: https://oscarliang.com/product-06wq

- GetFPV (12awg): https://oscarliang.com/product-4bun

- GetFPV (16awg): https://oscarliang.com/product-a8nh

- RDQ: https://oscarliang.com/product-l0p0

XT30 Connectors

- RDQ: https://oscarliang.com/product-6gvi

- GetFPV: https://oscarliang.com/product-0ipn

- Amazon: Amazonhttps://amzn.to/3l8PdY0

- Banggood: http://bit.ly/2zTIRD6

- AliExpress: https://s.click.aliexpress.com/e/_DkJfemp

XT30 16AWG Pigtail

Comes with wires soldered on.

- AliExpress: https://s.click.aliexpress.com/e/_DkQ06hP

- GetFPV: https://oscarliang.com/product-d6t7

- Amazon: Amazonhttps://amzn.to/3yvHtSU

- RDQ: https://oscarliang.com/product-aq6b

Tips for Using Wires and Connectors

What Gauge Wires for Extending Capacitor?

When extending a capacitor in your FPV drone, the recommended wire gauge will depend on the size of the capacitor and the amount of current it will be handling. But in general, the length of the wires are more important than the wire gauge.

For smaller capacitors (under 1000uF), you can use thinner wires such as 18AWG or 20AWG (like the motor wires). For larger capacitors (over 1000uF), it’s best to use thicker wires such as 16AWG. It’s important to keep the wire as short as possible to minimize resistance.

You can learn more about why and how to add capacitor in your drone in this article.

Soldering Techniques

Proper soldering techniques are important for creating strong, reliable electrical connections in your drone. Techniques for soldering wires and connectors include tinning, splicing, and using heat shrink tubing to protect the connection. It is important to avoid common soldering mistakes such as overheating the wire, creating cold joints, or using too much solder.

You can learn about how to solder wires and connectors in this tutorial.

Proper Cable Management

When routing wires in your drone, it’s important to keep them as short as possible to reduce the risk of interference and voltage drops. If the wires are too long, you can twist them to keep them neat and tidy, which also help against interference.

When connecting wires and components, ensure that they are securely fastened and will not come loose during flight. Loose wires can cause significant damage to your drone during flight and potentially lead to a crash.

It’s also important to avoid resting cables on top of the flight controller, apart from potentially causing interference, it could also be hitting the gyro which affect flight performance. Instead, try to route cables underneath or around the FC.

Finally, to help prevent damage to your battery lead solder joints during crashes, it’s recommended to secure the battery lead to the frame using zip ties. This provides stress relief and prevents pulling the solder joints during a crash.

More Info and Discussion

We have a similar topics on the forum if you’d like to learn more about this subject and like to comment.

Edit History

- May 2014 – Article created

- Apr 2017 – Article revised

- Nov 2017 – Added product shopping options

- Mar 2023 – Updated guide, added “Tips” section, updated product links, changed page URL

48 comments

Hey, do you know why in RC car racing we exclusively use ec connector and for what i saw, drone user use xt60 ? They are the same but, it’s just the plastic part. In car connection, the câble connect directly in the lipo, it’s an encased lipo with female soldered already. As there are no plastic connector, one could plug the cable wrong. Inside the car, the wires are designed so you can’t reach the wrong plug with the wrong cable. That’s the only downside i find for the drones. I never tried xt60 yet, but it’s seems harder to detach, ec connector slide in “banana style” and are easy, let say tunable for setting the strenght of holding.

I’m thinking about the lipo catching fire, you pull only one câble and it’s off. For the xt, you’have to hold everything. But maybe a nosmoke detector does that ?

Cheers, thanks for all the tutos here, it’s great

Thanks for the info Oscar! Quick question, is it a safe to use an xt30 to xt60 adapter from a battery that uses an xt30 connection to a drone that uses xt60, instead of completely switching out the connection type on the drone? Thanks!

Yes that should be fine as long as the smallest connector meets the current requirement – in this case the XT30.

Thanks for sharing this Great information, I was actually searching on What type of wire is use for 1404 brushless motors bec I am using my iflght protek25 motor to another frame, and it seems to be short in wire, so I need to solder a wire extension. can you help?

You can just match the wire gauge used in your motors. I think 26AWG is a pretty common wire size for 1404 motors.

Great info, thank you! I have been looking in the past for max current of AWGs but did not understand why they were so low. Thanks for that cable table :) I´ll consider it if I build a LiIon pack for my edf jets :))))

I just built a new drone with the speedy bee v3 f405 fc and I’ve hooked these up before and never had luck with them but this time I mad sure all was hooked up correctly and no bridges and when I plugged in my battery with smoke stopper it made a shinging sound so I unplugged it quickly.If there’s flux left on the fc,ascor vtx will that make a shinging sound?

I’m totally pissed because there’s nothing wrong with the build and it still made a sound like the fc was burning up.

Great article once again

When you say voltage does not matter, it does since power a cable can handle is W = V * I. So AWG 18 cable under 120V can handle 1.5A for 180W. The same cable at 7.4V can handle about 24A. Mind you cable spec varies from manuf to manuf, length of cable, it’s resistance and material to name a few impacts calculation. It is important that you are also looking at the right chart since a chart for 30V (RC environment) and a chart for 120V (home wiring) will be different.

We are discussing wires/connectors for FPV drone use, the maximum voltage we deal with are only up to 6S (25V)

You are completely wrong! Power dissipated in cable DOES NOT related to voltage passed trough cable. AT ALL.

Ohm laws says, that Voltage equal Current multiplied by Resistance. We have to use this formula to find voltage dropped in cable, then we have to use this voltage to find power dissipated in cable.

For example, 1 meter of 18AWG copper conductor cable has resistance ~0.02 Ohm. If we pass 1.5A trough this cable, voltage drop will be 0.02Ohm*1.5A = 0.03V and power dissipated in cable will be 1.5A*0.03V = 0.045W. If we pass 24A trough this cable, voltage drop will be 0.02Ohm*24A = 0.48V and power dissipated in cable will be 24A*0.48V = 11.52W.

I thought only the current passes…?

Interesting how each of you use slightly different wording and proclaims the other guy is wrong. A bit like conquista on arrival to America.

Somewhat off-putting to say anything fearing the only people reading are those waiting for new article/comment to shout “No, I have the biggest balls here.”

Thank you, great article!

I now see I was here when I was driving cars already xD

Very good info for me. thank you very much

Hi Oscar how are you? Really nice stuff here in you site, thanks for all data you provide !!

Just a quick question: is there any way to install GPS Modul to SucceX Mini F4 V2 Flight Tower System 2-6S with 500MW VTX??

Thanks in advance

Luciano

hello, I just recieved a set of 20Amp EMAX bullet ESC and noted that the PDB to ESC +/- leads were 20awg

I thought that a little low, I think 20awg is ok for the three ESC to MOTOR wires as the load is distributed acros 33% more wire but is that not too low of a guage for the power supply to ESC?

Hello Oscar. I’ve completed 5 inch quad build. Everything works the way it should but I haven’t flown it yet.

My question is about the wiring harness which connects 4-in-1 ESC with flight controller. Will those thin harness wires be able to supply enough current without burning down or sagging the voltage? The flight controller gets 6S battery voltage via the harness. Do I have to upsize the Vbat and ground wires by removing them from the harness and direct soldering 22 AWG or 26 AWG jumpers between the ESC main battery pads and the Flight Controller Vbat pads? Can I add more components like GPS to the Flight Controller with my current set up?

I used Lumenier LUX F7 Ultimate Flight Controller which supplies power to everything listed below:

Two micro eagle FPV cameras via 5V

TBS Unify EVO VTx via switchable Vbat pad

TBS Crossfire Diversity Nano RX via 4V5 pad

5V buzzer

Your help is much appreciated!!!

Your FC doesn’t take much current, the provided harness is fine.

Yea you can add GPS.

hi,

if i have a 4in1 esc does that mean i need wire that can handle 112a or just 28a

thanks,

Daniel.

Great information in this post, thank you!

Which wire size is suitable to connect the escs to a 40A rated brushless motor? I am always using the default cable attached to the motors But my new motors came with wires and motors detached (have to solder the 3 wires to the pads on the motors). Do I use a 40/3 =~13.3A rated wire ie. Awg 20?

Very nice and informative article. Thanks for sharing this.

My quad DH410 acts weird for what I need your advice. When I first built it, it was about 1400gms (with no gimbal and camera) including 4000mAh 4S lipo. It used to give about 11 min of hover. But then I decided to slim it down. I made many changes in wiring and connectors esp and successfully reduced it’s weight by 100-120 gms. Mainly I removed all bullet connectors from each and motor and also reduced the wire gauge of all 4 Sunnysky X2212 980kv motors from 18 to 22.

Now Pixhawk gives low battery alarm in just 30sec of flight ending up in RTL. BUT with 2200mAh 3S battery, it still flies for 9 min (total 950gm wt). With 4000mAh 4S, just 30 seconds. I have 2 batteries – 4S 4000mAh, and with both it behaves same. So can it be a gauge of motor wires triggering RTL? Telemetry shows voltage literally crashing from 16.4v to 13.8 in few seconds. Please advise; thanks.

I think the problem you described is caused by something else though, try swap the wires back, you shouldn’t really change out original wires unless they need to be upgraded to larger gauge. Also 4S is going to draw more current than 3S, so you really shouldn’t use smaller Awg wires.

Thanks Oscar. Sorry for toooo late reply. The problem solved long ago, almost in 1-2 days of above question. It was actually the led wires that were creating the problem. Now quad giving me good flight time with 22 gauge wires.

Hi Oscar I have these emax Bullet 30A esc’s gearbest.com/multi-rotor-parts/pp_603577.html what wire do you think the red and black ones are?

18awg :)

Hi Oscar,

What AWG wires would you recommend for the following:

[1] from [Flight Controller] >>> [KISS ESC 2-5S 24A Race Edition]?

[2] from [Battery 3S/4S] to [PDB]?

Thanks

Dave

Here :) http://intofpv.com/t-what-awg-wires-to-use

Hi Oscar,

I have these ESC’s

(banggood.com/de/DYS-BL20A-Mini-20A-BLHeli-ESC-OPTO-2-4s-for-RC-Multicopter-p-975798.html)

and want to know the cross-section of the power cables (red and black).

Do you know the thickness of these wires?!

Thanks in advance for your help!!!!

Markus

those are 20AWG wires, you can look up the thickness now :)

I have 20A littlebee’s and 2300KV E-Max. Should I then go for the theoratical values of:

4 X 30 A (Littlebee’s Burst) which makes about 120 AMPS, needing 12 AWG?

Still need to buy batteries, but can’t find the AWG size of them (looking on HobbyKing)

nah just match the size of the cable with the batteries you are using, and you should be fine. For most 1800mah 4S 65C for example they normally use 14Awg.

Oscar i noticed many 4S battery are now coming with 12 AWG wire (Lumenier 1300mAh 4s 75c LiPo Battery (XT60), PULSE Graphene 1550mAh 4S 14.8V 95C Battery w/ XT60, Thunder Power Adrenaline Series 1300mah 4s 80c, Tattu etc, etc, etc) Should i still use a 14 AWG as usual or i should upgrade my battery pigtail?

If you don’t mind the few extra grams, I think it’s safer to use 12awg :) But I don’t think 14awg would cause any problem either :)

Thank you for this useful article.

Just wanted to ask, I’m planning to tranfer my existing quad to a 500 frame and would need to extend the existing wires I have from my 2212kv motor to my 20A ESC. I had trouble finding 20AWG wires and only found 18AWG wires. Would there be any specific issues I might encounter if I hook those up to extend the existing wires?

Looking forward to hearing from you!

apart from more weight, it’s absolutely fine running thicker wires.. or combining different awg wires, shouldn’t be any issue.

Hi Oscar,

The ESC KDE 35A might not be the correct esc. Typically for the motors that are being used the KDE 55A are recommended.

Hi Oscar,

Thank you for writing very useful and informative articles. They have certainly helped enormously with my quad build.

I would like to ask you advice in regards to wire type when connecting the ESC signal wires to the FC.

I run BL30A ESC (Opto). I plan on replacing the signal and ground wires that are on the ESC’s with just a single signal wire. (The ESC’s will be grounded to the PDB). I would like some advice if possible in regards to wire type. Should I run stranded bare copper wire or tinned copper wire?

I have read that tinned copper wire provides extra durability to the copper wire but I am wondering if bare copper provides better signal performance than tinned?

Also what AWG do you recommend using for the ESC signal wire, 26AWG? or thicker?

Thanks in advance. :)

Hi Chris

Any electrical wire should be fine. 26awg is perfect, signal wire doesn’t carry much current, and it’s usually fairly short anyway.

So i’m having an oscillation problem on a small quad i built with 18a spider esc’s. The thing is small, 141 grams with battery. I’ve tried every pid combination i could thing of, tpa, etc, etc, but still it oscillates at full throttle. Googling it i found someone that supposedly fixed their oscillation by changing to a higher gauge wire for the escs, so i looked over all my wires and the battery wire is 18awg, but my jst power wire is 22awg. I’ve ordered some 18awg jst connectors, but i wonder if this bottle neck in the power distribution can cause such oscillations? I have the esc’s soldered to a pdb.

anything is possible in this hobby :D but 22awg wire for the main power cable does sound small, and when ESCs might not get enough power at high throttle and start to struggle.

best thing to do is check your motor/prop combo and see how much current they draw to work out best awg wire to use… otherwise you can just use same awg wire on the battery.

sorry, it’s actually 20awg, but still it’s a bottle neck. it could be a lot of things i know. I end up replacing the esc’s with dys 20a just to rule them out i’m sure.

Hi Oscar,

I have a question regarding the jst connectors. I have a 3s lipo 1500 mah 35c with xt60 connector with 14 or 16 awg. I would like to do an adaptor for jst but my jst wires are quite fin (22 awg). Would that be problematic? What could happen? It’s only to power a light plane so 1 engine esc and 3 servos! Thanks!

depends on your max current draw through that JST connector? For around 10A your 22awg wire should be fine… you might get away with a bit higher current going through it, but it might start to heat up.

Great article and very informative!

I would love to have your help with something which is related to this article.

My X8 octocopter won’t lift off when I add more payload to it. Right now the AUW is 15lbs (with no gimbal, cameras or FPV accessories). When I connect one battery it hovers fine but will only fly for a few mins, but when I add two batteries, in parallel, then due to the added weight it takes off for two seconds and lands hard as it starts yawing to the right.

My power distribution board had 3.5mm connectors but changed them to 5.5mm Castle Creation connectors. Because of that I replaced also the bullet connectors from the ESCs end side to 4mm. I also upgraded the wire to 10AWG but even after doing all that I’m still having the same issue. Now the only connectors I haven’t replaced yet are the motor bullet plugs from the motors, as well as the connectors on the speed controllers to the motor side which are 3.5mm.

The propellers I use are 15×5.5 T-motor equivalent.

Frame: Gryphon Dynamics GD-X8

Motors: KDE FX4014 380kv

ESCs: KDE 35A

Battery: “MonsterRC” 35C 6s 10000mAh

FC: NAZA V2 (with low voltage alarm disabled)

AUW: Estimated to be 14-15lbs without gimbal, camera or other components.

Any advice would be greatly appreciated!

sorry i don’t have much experience with multirotor of that size.

but by the sound of it, it’s a power issue? could you upload a video in this group?

facebook.com/groups/Copter.Fans

I’ll answer it. That’s far too heavy a battery for the power being generated by those motors. 20,000 6s in insane. Try a 5000 6s at most