MIT researchers have developed an innovative toroidal propeller design that significantly reduces noise levels compared to traditional propellers. The toroidal design features a ring-shaped blade that encircles the propeller, helping to suppress the noise generated by the rotating blades. This new design could be particularly useful in areas where noise pollution is a concern, such as urban environments or near residential areas. By offering a less acoustically intrusive drone, these propellers may accelerate the acceptance of drones for various applications, such as aerial deliveries, cinematography, industrial or infrastructure inspections, and agricultural monitoring.

Table of Contents

Where to Buy?

You can now try this propeller design from Foxeer, they call their version the Foxeer Donut 5145: https://oscarliang.com/product-ysjc

There will be more variants made by different manufacturers, I will update it here once I hear more.

What Makes Toroidal Propellers Unique?

The toroidal propeller by MIT consists of two blades looping together so that the tip of one blade curves back into the other. This closed-form structure minimizes the drag effects of swirling air tunnels (i.e., vortices) created at the tips of blades and strengthens the overall stiffness of the propeller. These features reduce the propeller’s acoustic signature.

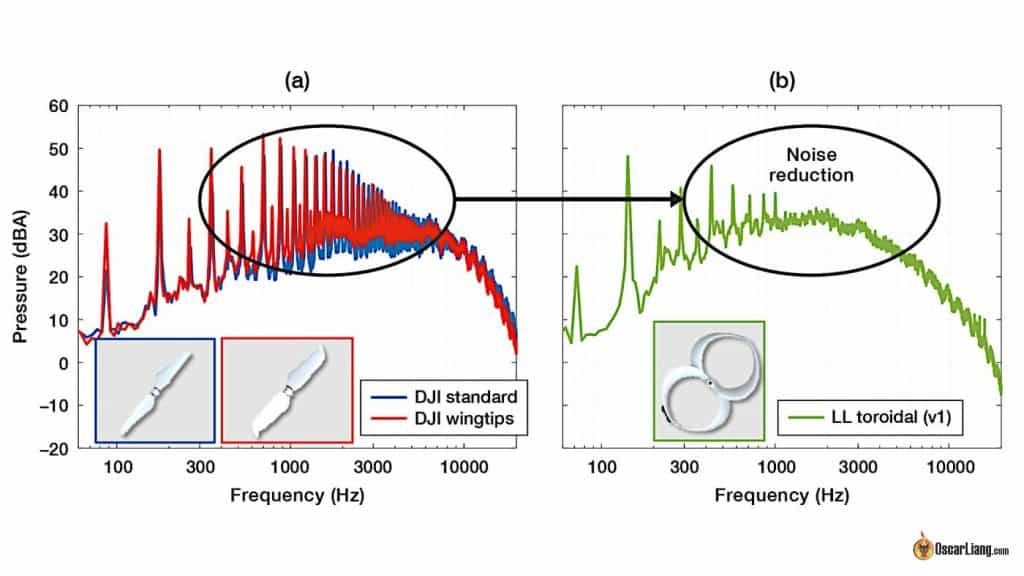

Without adding weight, increasing power draw or sacrificing thrust, toroidal propeller reduces noise by decreasing signals in the frequency range to which humans are most sensitive. This means they are slightly quieter than traditional designs, with reduced noise levels in the 1-5 kHz range. They also offer a boost in efficiency at certain RPM ranges.

Due to the unique design of the toroidal propeller, it’s also less likely to cut, catch, or clip objects or surfaces in the drone’s path than traditional propellers with sharp and pointy ends.

The comparison between conventional propellers used on DJI’s drone (a) and the toroidal propeller (b) demonstrates the significant noise reduction achieved by the toroidal propeller.

The traditional propellers we commonly see in FPV drones function by creating high pressure underneath and low pressure on top while spinning through the air. This mechanism creates thrust that pulls the propeller through the air. However, a high-pressure rush towards the low-pressure side at the tip forms a vortex, causing noise and energy loss.

The toroidal propellers introduce a game-changing design. These twisted and looped propellers, aiming to minimize the vortex effect, ensure high and low-pressure air remain apart, thus reducing noise and improving efficiency.

Designing and Creating the Toroidal Propellers

Following a publication from MIT, FPV enthusiasts have embarked on 3D printing toroidal propellers to verify the claims of the researchers, who mainly promise a more “acceptable” sound. The aim is to check the impact on thrust, efficiency, stability, and to evaluate the performance of the propellers. Additionally, various 3D printing materials are being tested to optimize propeller balance.

Unlike traditional propellers, there are no readily available models for Toroidal propellers. To test them, the propellers had to be designed from scratch and 3D printed at home. There’s definitely room for improvement, so it’s important to take the results with a grain of salt.

Unfortunately, manufacturing these toroidal props can be a challenge. Unlike traditional FPV props that boast a smooth, shiny surface due to the injection molding process, we are still relying on 3D printed versions for toroidal props, which result in a textured surface.

Testing the Toroidal Propellers

To evaluate the performance of these propellers, three main tests were conducted: efficiency, handling, and noise. A standard battery flight test was used to determine efficiency, while the handling test assessed overall control and maneuverability. A comprehensive noise comparison was also performed to evaluate sound efficiency.

Numerous drone enthusiasts have successfully printed and tested these toroidal propellers on actual FPV drones. Notably, the famous line-of-sight drone pilot, quadmovr, tried these props and showcased impressive performance in his video. However, it’s worth considering that his exceptional flying skills may have contributed to the perceived propeller performance.

The sound produced by the toroidal propellers is different from that of conventional propellers. Despite the rough treatment of the quad and its propellers by quadmovr during line-of-sight flights, the PETG-made propellers proved strong enough to accommodate highly committed flights.

Observations and Results

Regarding safety, toroidal propellers could potentially be safer if designed with curved edges to minimize the risk of laceration. However, their primary selling point appears to be the low-pitched prop noise they produce.

In terms of efficiency, the toroidal propellers tested so far have shown a significant reduction in flight time and performance compare to traditional propellers, with the drone only able to achieve less than 50% of its original flight time. This loss in efficiency raises questions about the value of trading efficiency and stability for noise reduction.

Limitations and Considerations

While toroidal propellers may be quieter in the demonstration by the MIT researchers, questions remain about their efficiency. The MIT team notes that the toroidal propeller achieves thrust “comparable” to that of a multirotor drone propeller, but the FPV community is debating whether this design could potentially reduce the propeller’s thrust and increase drag, impacting overall efficiency. Further testing will be needed to determine the trade-offs between noise reduction and efficiency for this innovative new design.

It is essential to note that the testing we have seen conducted were mostly based on a 3D printed replica of MIT’s Toroidal propellers, not the exact design. The 3D printed parts had a rougher surface and were not as strong as injection-molded parts, potentially impacting the results.

Interest in the FPV Community

Leading FPV drone propeller manufacturers, Gemfan and HQProps, are already developing their own versions of toroidal propellers. These designs are currently undergoing testing.

Here are the Gemfan toroidal propeller prototypes:

And the HQProp toroidal propeller prototype:

Conclusion

The MIT announcement generated significant excitement, sparking widespread experimentation with 3D printed toroidal propellers. Overall, the toroidal propeller design represents an exciting new development in the field of propeller design and has the potential to be a game-changer for certain applications where noise reduction is a top priority.

Toroidal props, though exciting and offering noise reduction benefits, may not completely replace traditional props just yet. They currently lag behind in terms of efficiency and thrust, and their heavier weight could affect the responsiveness and stability of the drone. That could also be due to the lack of optimized design and manufacturing for this type of props.

That said, if noise reduction is a priority – say, if you’re flying in populated areas where less disruption is preferred – toroidal props could be a fantastic choice. As this technology evolves, there is no doubt we will see further developments that may bridge the performance gaps.

For the performance-driven pilots who need maximum responsiveness and power, traditional props may still be the go-to choice. Despite the advent of this fascinating technology, traditional props have their place and advantages in the FPV drone world.

For now, if you’re looking for the best propellers for your FPV drone, we recommend sticking to the options listed in our recommendations: https://oscarliang.com/propellers/#Recommendations

Edit History

- Mar 2023 – article created

- May 2023 – added first product link to this prop design

4 comments

Are ducted fans a better idea for drones? Like Avatar?

“The sound produced by the toroidal propellers is different from that of conventional propellers, but it is superior to that of 8-blade propellers.” Wasn’t the sound of the 8 blade propeller smoother/quieter than the toroidal propeller in quadmovr’s video (his own judgements). Though, I do understand the reasons behind what might’ve affected the sound, perhaps I missed the part where it explains why “it is superior” in the article.

I haven’t seen any actual cases where the toroidal propeller was actually better than the conventional ones in any metric around the internet. I found one that actually seems to be working used by Zipline ‘Zipline’s quiet propeller’ which is getting used for actual use cases instead of it just being a fad and something that has unbiased research behind it.

You judgement of performance is based on badly designed versions of the propellers. The ones made with sliced sections of cylinders are extremely simplistic and horrible aerodynamically.

Your judgement of…