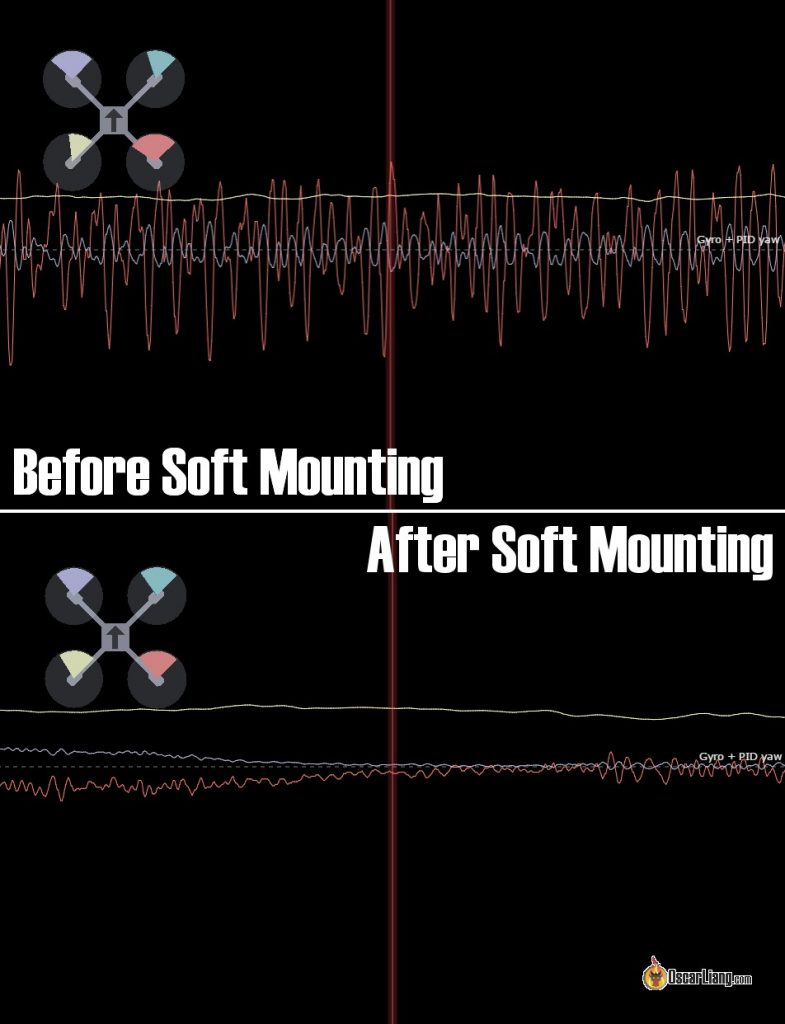

With high-power motors, the flight controller can experience high-frequency mechanical noise, leading to vibrations and oscillations during flight. Soft mounting is a technique used to isolate vibrations from reaching the gyro sensor on the flight controller.

Check out this list for more fpv drone building tips.

Table of Contents

What is Soft Mounting

Soft mounting became a hot topic in 2017 as vibrations became a significant issue due to more powerful FPV Drone motors, faster PID algorithms, and Gyro sampling rates.

You can soft mount both the flight controller and the motors to reduce the amount of mechanical noise from the motors reaching the FC/Gyro.

Benefits of Soft Mounting

While you might manage to fly without soft mounting, if you ever face issues like oscillations and twitching, the first recommendation is always to soft mount your flight controller and/or your motors.

Other benefits of soft mounting the FC and motors include:

- Smoother flying experience

- Allows for higher PID tunes and easier PID tuning

- Cooler running motors

- Reduced video noise (as mechanical vibrations can translate into electrical noise)

Though soft mounting can significantly help with particularly noisy builds, it doesn’t eliminate all vibration frequencies. If your build isn’t initially noisy with the motors and propellers, you might not notice a substantial difference.

For certain gyros, soft mounting is essential for viable flight. For instance, with the ICM-20608 IMU, if you find this gyro on an FC, soft mounting the board is crucial for optimal quad performance.

FC Soft mounting

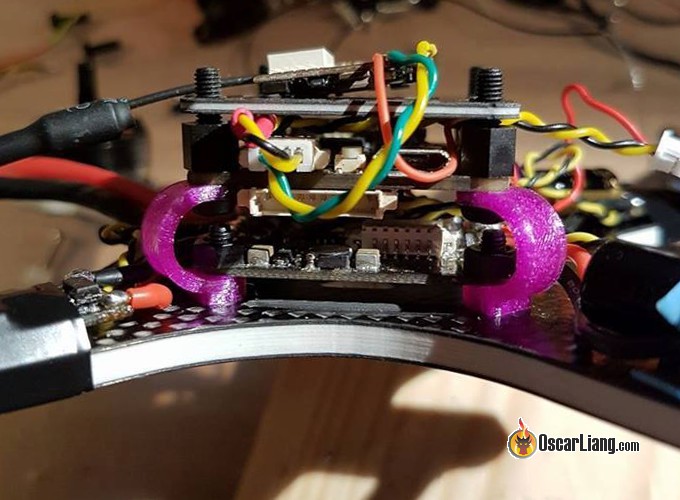

Here are some ideas to soft mount your FC:

- Anti-vibration M3 bobbins (Buy: AliExpress | Amazon | GetFPV)

- 3D printed TPU mounts (following image)

- O-ring (Buy: AliExpress | Amazon | GetFPV)

- Grommets

- Foam tape

My favorite option is the anti-vibration bobbins. They are easy to get, affordable, and work exactly like ordinary standoffs.

O-rings generally aren’t the best choice because they are too thin and often made of harder material that doesn’t effectively dampen vibrations. Moreover, the screws can still transmit vibration through to the flight controller.

Raceflight’s Revolt FC has a novel way of isolating vibration using grommets (RF calls them “gummies”), but this only works if your board has oversized holes to fit these grommets.

One of the oldest yet effective methods is to use double-sided foam tape. This allows you to forgo screws and standoffs entirely and simply stick the FC to the frame. However, this approach means you cannot stack anything above or below the FC, such as a PDB or 4in1 ESC.

In addition to soft mounting your FC, ensure nothing else touches the FC that could transfer vibration from the quad, such as wires or zip ties.

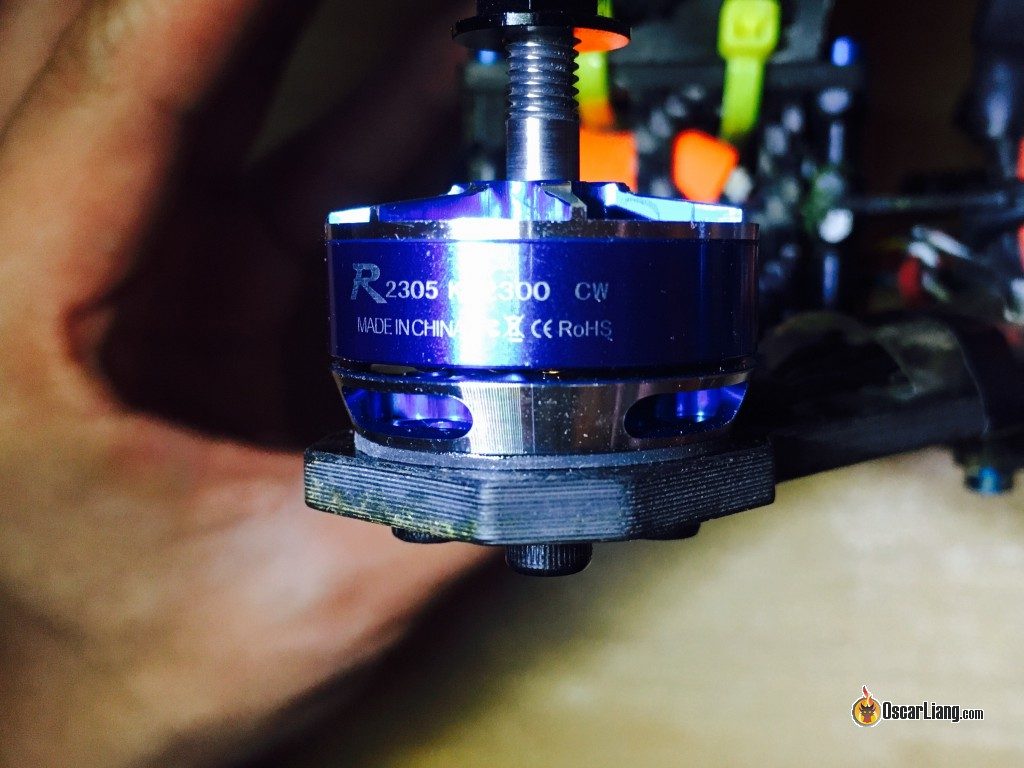

Motor Soft mounting

The primary source of vibration in an FPV drone is the motors, as they are the only moving parts. Therefore, soft mounting can be very effective if you can stop the vibrations right where they start before reaching the flight controller.

The damping effectiveness can be influenced by the attached mass and the dampener’s elasticity. Since FCs are lightweight, the damping might not be sufficient. Damping at the motors could be a better option, as they are heavier than an FC.

Update (21/05/2017): After soft mounting motors for a few days, I found it to be too much of a hassle. You can’t tighten the motor screws fully, so you have to check them every session or risk screws falling out during flights. Although it could be a more effective way of isolating vibrations than soft mounting the FC, the results can vary greatly as you can’t ensure the same tightness in the screws for all 4 motors. So, I think soft mounting the FC is more practical, and I might just do that and not soft mount my motors in the future unless they are really problematic and I have to.

You can use many different materials for soft mounting motors in a mini quad:

- Electrical tape (3 layers or more)

- TPU 3D printed motor mounts (Buy: AliExpress | Amazon)

- Rubber sheet cut specifically for mini quads (such as these – Monkey & Gorilla-Rugz)

- 3M mounting tape (double sided)

Be aware that tightening the motor screws all the way will compress the vibration-dampening material, making it less capable of absorbing vibrations. Ensure to apply Loctite on the screws as well, as you are leaving the screws less tight.

Here is a good discussion too on our forum.

Update in 2024

Soft mounting is still relevant in 2024, but it’s no longer a concern for most builders.

Thanks to advancements in software filtering, there’s no need to soft mount motors anymore. With a clean build and a quality FC/gyro setup, you should be good to go.

Nearly all flight controllers now come with rubber grommets that effectively dampen vibration, eliminating the need to purchase additional anti-vibration hardware. However, ensure that you don’t overtighten the nuts, as this can reduce the effectiveness of the vibration dampening.

13 comments

I know this post is 3+yrs old, but it was so pretentious I had to reply…..

Well actually Paul, you super smart guy you, NOAD, Merriam Webster, OED, Dictionary.com, Random House and Wikipedia all have slightly different definitions, depending on if it’s a noun or a verb, but they all agree that unless writing a federal document, or something super formal, “dampen” can be used for either action. Merriam Webster and one other have Dampen as to deaden, or get rid of or lessen something physically, like sound waves or vibrations. Technical engineers, 20yrs ago, dampen was to wet damping was to reduce vibration, today most engineers use dampen for both. If you’re going to act like an elitist grammar nazi, at least complain about a word that is fragrantly misused.

“fragrantly”

Outstanding.

our quads are completely submerged at all times in a medium: oxygen , co2, nitrogen, and many other various gases no matter what its “submerged” in if its connected tightly to something there will be as much vibration as the moving parts give off as vibrations through the frame so to damp or absorb those vibrations only prolong the life of whatever part needed to have less movement or vibration. With quads it should improve the gyro /fc performance and accuracy to a level which may be noticable or unoticeable depending on how well the particular human can perceive things or if he succumbs to the placebo affect which happens more than you might think but i guess the black box could prove them right or wrong… but if it’s faster in the races or you enjoy it more thats all that matters and if it can save you money in the long run of course.

i tried foam between the FC and the PDB below it, fully floating and only held down with a band like a hairband but stronger. Checked the gyro results in motors tab and went from numbers of 7 with rubber bobbins down to numbers of 4.

Improvement, yes, reliable, we will see.

So be careful with boards that connect to eachother such as the hobbywing xrotor AIO F4 with the 40 amp esc. I found that using the rubber bobbins between each board had too much play and was ripping out the connection point to the pdb/esc and damaging it beyond repair. After (2) being ruined I went to nylon standoffs with a rubber ring on both sides.

Hi Oscar,

This is the first reply I leave. I’m ready loads of your articles and am very impressed and happy about them, thank you :-)

I’m still quite new to quads and am still trying a lot of different things. What do you think about the combination of soft mounting your FC with the M3 bobbins you listed and the motors with o-rings? I agree that for something as lightweight as a FC, the o-rings are to hard. But for something as “heavy” and force loaded as the motors they might be great. I already tried silicon pads, but they usually don’t fit very nice and feel too soft almost. Silicon o-rings are a little harder but still very rigid. Any thoughts on this?

Thank you very much, I hope there is a lot more coming from you.

Best regards

Adrian

Hey Oscar, did you try to soft mount the motor with the M3 stand-off bobbins. Sadly I only have 4 of them lying around, but it fits really well. The screws must be shortened by a millimeter or two.

Motor damping is not as good as we think. We add a degree of movement. So for high frequencies oscillation is ok but for low frequencies, it could be amplify in fact.

Normally, you chose the damping system knowing the frequencies of oscillations. It more efficient, because every damping system need to be adjust.

Hi Oscar,

I attached a Piko FC on 30.5 mm mounting holes with zip ties for an obvious reason.

I wonder if it reduces vibrations… but that might interest you…

Nice article btw…

zip ties are probably too solid and doesn’t absorb much vibrations… also it’s hard to keep FC perfectly leveled i presume..

Please. To dampen something is to get it wet. To damp is to limit vibration. We don’t dampen our quads.

My dictionary tells me that they mean the same thing :)

but you are right, “damp” is a more common word to use for reducing vibration :)

You are both wrong. My experiments have shown that my quad has the least vibration when it is completely submerged.