Polystack is an innovative modular flight controller system by Chickadee Tech. Instead of taking everything on one single FC, Polystack allows you to stack multiple extension boards on top of the FC. Therefore you can mix and use any functionality you want on your quad.

Polystack is available at Chickadee.tech. They are so kind to offer our readers a discount code for $20 off orders over $100: OSCAR20 (valid until 14 Sep 2016).

Polystack Modular FC System Overview

The Polystack boards are packed in paper bags. On the sticker it explains what spacers are in the bag, and installation instruction.

This is the content that come with the F3 FC for example.

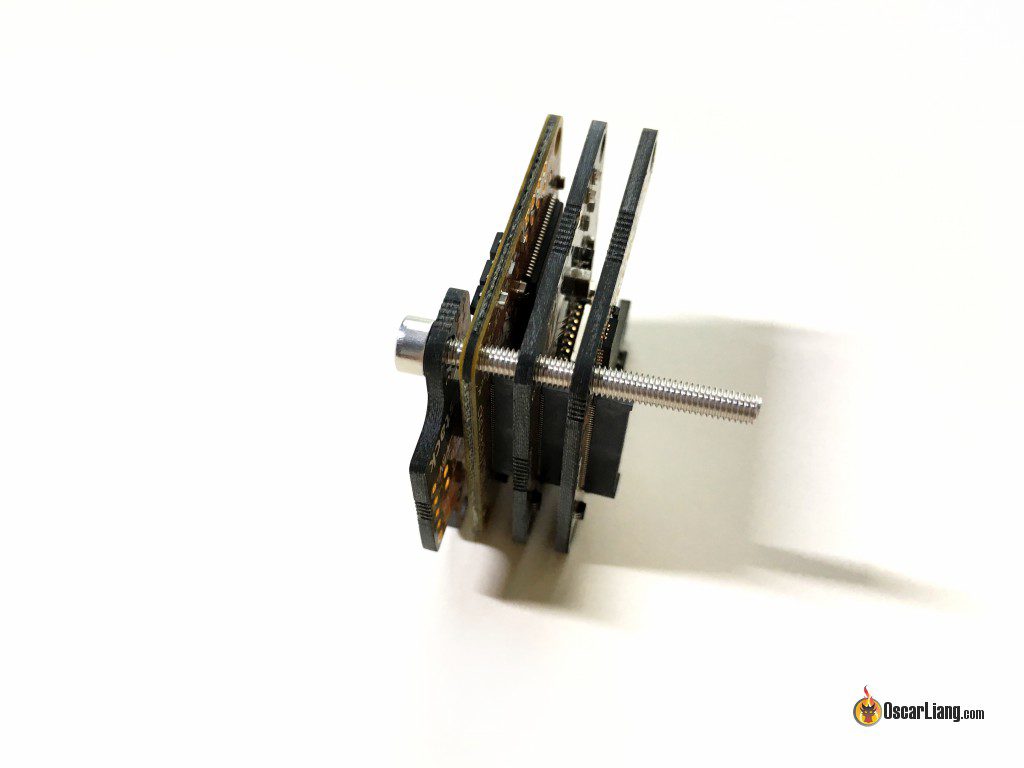

The stackable boards are connected with 80-pin Polystack connectors (DF40), which has room for 1.8A of current, 6 GPIO, 12 timer pins, 1 i2c, 8 UART and 3 SPI. According to Chickadee, you can stack up to 7 boards without pin conflicts!

All the boards are standard sizes of 36mm x 36mm, with 30.5mm x 30.5mm mounting holes.

Chickadee calls these extension boards “mods”. Currently (15 Aug 2016), the available mods include:

- FrSky D4R-II cradle

- FrSky X4R-SB cradle

- Serial breakout

- MicroSD board

- micro MinimOSD cradle

- Pololu Power Cradle

- Generic receiver cradle

- Testing and debugging boards

And there are 2 FC boards you can choose:

- F3 FC

- F4 FC

There will be more mods available, such as autonomous navigation mod or even VTX I would imagine. What we are all looking forward to the most would probably be something like an 4-in-1 ESC, hopefully with PDB integrated as well.

The project is open source which means anyone can design modules for this system. The design files are available their website.

I will show in a bit more detail of the modules I received.

Flight Controller Board

The flight controller is very basic, it has a processor and a MPU6000 (accelerometer and gyro), along with 4 header holes for ESC signals. But thanks to the Polystack connector, there are 5 hardware serial port (UART) available. Normally on other F3 FC there are only 3.

Both the F3 and F4 FC have the MPU6000 connected via SPI.

Pololu Power Cradle

The power cradle requires an additional Pololu voltage regulator (you can also use any other voltage regulator to connect to the cradle with wires).

The power connection on the power cradle and back of the FC is a 20 pin connector.

I personally think the design of the power cradle can be better.

Not only needing an extra voltage regulator, it also sticks out on the back which might not fit on all the frames. Chickadee explained it was designed this way for flexibility and simplicity. However it’s good to know that Chickadee is working on a PDB that won’t stick out, and also comes with a built-in 5V voltage regulator.

I think the BATT and GND pads for LiPo connector need to be made bigger for easier soldering, and give more clearance between the 2 pads to avoid shorts.

Frsky Receiver Cradle (X4R-SB and D4R-II)

To install the RX on this cradle, the users first need to de-pin the receiver, then direct solder the RX on top of the cradle (maybe with header pins). The extension board also provides pins for telemetry or Smart Port, where you can solder the wires directly to.

This is for the X4R-SB RX.

This is for the D4R-II RX.

The cradle has already jumped the pins for you to use PPM.

Generic Receiver Board

In case you are using something rather than Frsky D4R-II or X4R-SB, there is also a generic receiver board you can get.

It supports RX including serial (SBUS), PPM, 6ch PWM. Spektrum users can also use this board. But in my opinion, if you use this board, you lose the modular, clean, compact advantages of this system.

MicroSD board

This board is the best example of this modular FC system in my opinion. It requires no fiddling, and it’s plug and play. It allows you to insert a micro SD card, and record blackbox data on it.

On the SPR Evo FC, there is a built-in SD card device there for blackbox log recording. People don’t use blackbox hated it, as it’s a waste of space and cost. In Polystack, now you can take it or leave it depends on your preference. You can even remove it after you have tuned your quad, how handy is that?!

Dual Serial Breakout and Debug boards

I don’t see myself using these 2 boards.

The Dual Serial Breakout board simply gives you access to 2 out of 5 hardware serial ports (UART) on the FC. It allows you to run other serial devices that don’t support the Polystack connector. Or if you need to place that device further away from the FC stack such as a GPS receiver.

The Debug board gives you access to all the pins in the Polystack connector. I guess this is handy for hardware/software developers and experts.

Customized version of Betaflight

Polystack uses a customized version of Betaflight (currently V3.0). Chickadee created an awesome feature in it called “AutoConfig“. It automatically detects what boards are present in the system, and will turn on the features and settings required for it to work. This makes popping mods off and on much easier.

For example when you stack the Micro SD board, Betaflight will automatically turn on blackbox feature, and set recording resolution to 1:1 (because it’s connected via SPI it’s fast enough).

Users no longer have to worry about changing settings, features or even serial port for the devices they stack on.

Hopefully this will be pulled into the official release of Betaflight in the future. Their firmware can be found on Github: https://github.com/chickadee-tech/betaflight/releases/

The Little Detail

Table of Contents

Board Connection Order

It doesn’t matter in what order you stack the boards/cradle. The only exceptions are, power cradle has to be under the FC, and the rest of the boards stack on top of the FC.

How Many Mods Can You Stack?

If you have bolts long enough and the space, the auto-config will work with up to 7 mods. Also make sure the FC bolts are long enough (or not too long) to support all of your boards, and fits in the frame nicely.

In my experience most frames have the 30mm standoffs which should be enough for the basic boards plus a mod or two.

What happens if we run out of UART’s?

There are 5 UARTs on this FC system, so it’s extremely unlikely that we would (for now), but out of curiosity I asked him anyway. Quoting Scott’s comment in our conversation:

When you run out, you are out. The AutoConfig system should be able to warn you when that happens though.

However, its not very likely because the F3 has 5 hardware UARTs and the F4 has 6. I even added some timer pins after that just in case softserial is needed. I haven’t implemented that though. The connector itself can hold up to 8 UARTs which the F7 can provide if I remember correctly.

If you are curious all of the pin definitions are here: https://github.com/chickadee-tech/polystack/wiki/Pin-Definitions

What’s the Height of the PolyStack?

It really depends on what you run. I think a common selection of modules would be – the Power Cradle + FC + X4R-SB Cradle + Micro SD board as assembled below. The height of the stack is just under 20mm. (if you swap out the Micro SD with a MinimOSD cradle I imagine it should be around similar height)

Future extension boards?

4-in-1 ESC

One popular request for Chickadee Tech is the 4-in-1 ESC board. I asked Scott, owner of Chickadee and he said:

I don’t think ESCs are a good fit for a stack because of the heat they generate and because ESC development is moving really fast. Its hard to keep up with that innovation when designing for a custom form factor.

We have an issue for this already here: https://github.com/chickadee-tech/polystack/issues/4

I’m with you though. I’m worried about the pace of ESC innovation surpassing any special Polystack ESCs I would design. The only thing I’d be tempted to do for native ESCs would be an experimental board where the main microcontroller controls the FETs directly. I’m curious what latency that would remove.

If they are ever going to develop this board, I really want to see them integrate the ESCs on 1 single board if possible. TBS Power Cube for example, each ESC takes up a whole layer and they take a lot of vertical space. Maybe an ESC cradle where you could just solder the ESCs on it, like the KISS ESC carrier.

OSD board/cradle

Currently the OSD module requires an actual micro MinimOSD to be directly soldered on top. I asked Scott why they didn’t design the board to carry all the OSD components, and he replied:

I’m still thinking about a “native” OSD. There are a couple reasons I didn’t start with it:

1) Legit MAX chips used by MinimOSD are more expensive than the available Micro MinimOSD (which most assume use knock off MAX chips) so it was actually cheaper this way. People may already have them too.

2) I was already designing a bunch of circuits and I wanted to minimize complexity.

I would love to make an OSD going forward without a MAX chip. I think its an area ripe for innovation. I’m tracking the start of the native OSD development here: https://github.com/chickadee-tech/polystack/issues/9

That said, its something I want to do in the future. Hopefully it’ll not be MAX chip based and allow for pixel based OSD rather than character based.

I think it is possible to have OSD overlay on VTX video, just using micro controller without the MAX chip. Like the BrainFPV board, I think (correct me if I am wrong) while the STM F4 MCU runs the PID loops, it can also handles the OSD with its great processing resource. But this requires a real-time OS to do, and currently betaflight/raceflight aren’t. That’s why BrainFPV can’t support BF or RF because it would lose its OSD feature.

My First Impression

I love the concept, and they still have some more work to do I think

- IMO they should minimize the use of “Cradle” as much as possible, and build the components on the actual boards. So users won’t need to buy separate parts, and do extra soldering

- It needs a better power solution, ideally a single board with integrated voltage regulators and filters

- Maybe I am just being picky :) But since customers are paying premium price maybe they deserve some better packaging rather than paper bags? :)

Pros

- You can buy/mix any features you want in your FC system

- The AutoConfig feature in the custom firmware “knows” what hardware is in the system and will change settings for you automatically

- Excellent hardware quality

- Easy “plug and and play” solution – great if you need to swap out something in the field quickly

Cons

- High price

- The connectors are tiny and appears to be fragile. The datasheet of DF40 connectors states that they only have 30 mating cycles, so extra care should be taken. Also dirt could get into the connector? Might need a cover or something on the top board

- It seems to be a compact idea to have everything stackable, but with the current design it’s not really that compact, because every feature takes up a whole layer of space

- Spacers for each boards are different and it can be really confusing. This is due to each board are different height

I love to support Innovation like the Polystack, but the cost is a big factor for many of us. Each Polystack board costs and some of the boards are just cradles. It means you still need to purchase additional components such as Micro MinimOSD, receiver, Pololu voltage regulator and it adds up quickly. As a start-up company, it’s understandable that their first batch would be expensive, because they only produced a small quantity. But hopefully the price could come down when they increase their production scale.

2 comments

How much??? And when will itmactually be completed. As in when will everything be right?

I think that’s a great step into a real average consumer. Today there are too many boards with to many options, developed and being obsolete in a such short time that makes very hard to a new user to build and fly his/her quads easy. This, as well as the TBS Power Cube are the best attempts to build a standard. The only way this modular system can grow is being open source. I wish the best for this project and I hope to be a part of it!