Whoopee is a “Tiny Whoop” like, 3D printed micro quad frame. It’s designed to fit 8.5mm motors and many Cleanflight-compatible FC. Whoopee’s 3D printing files are free to download, you can also purchase it from us.

Why Building Whoopee?

Tiny Whoop is tiny and fun to fly, but it also faces some problems:

- lacking power

- lacking flight time (1min?)

- unable to tune PID, rate and expo

- locked down to Spektrum receiver – or using its own transmitter

- very fewchoices of battery and motors, and always hard to get

That’s why I decided it’s time to design an “Inductrix” frame for the 8.5mm motors, that also fits a Cleanflight compatible brushed FC. It gives you the flexibility in both software and hardware, while getting the advantage of a Tiny whoop.

It’s not as tiny nor as light weight compared to the Tiny Whoop, but it’s still tons of fun to fly.

Motor to motor distance is 10cm, and the frame weights are (weight depends on material and print settings, I am using PolyMax filament):

- Main body frame – 9.3g

- FC Plate – 0.9g

- Camera/VTX Mount with protector- 1.1g

- Whole frame assembled with zip ties is around 12.6g

Thanks to Scotty for coming up with the name “Whoopee” :) Here is a demo video I made yesterday.

Whoopee Micro Frame Closer Look

It comes with 4 parts: Main body, FC plate, camera mount and a VTX antenna protector.

Top and bottom of the frame.

Table of Contents

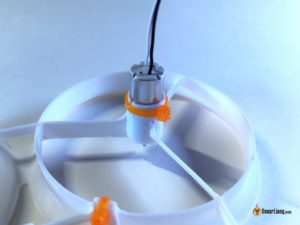

Flight Controller Mount

The FC plate has 2 holes on both sides, which can be inserted into the pillars on the main body. Then match all 4 holes at the corners, and put a zip tie through them.

The width of the FC plate allows any FC smaller than 26mm. That means it supports the Lulfro FC, Micro Scisky (aka Quanum Pico), the new Brushed EVO F3, and the Multiflite Pico.

Motor Mounts

One problem I found with 3D printed frame is heat expansion. This is a big problem for the motor mounts. Motors sometimes could fall out because motors get very warm. My solution to that is to leave some slots on the mount, and hold the it tightly with a ziptie and it works really well.

VTX / Camera Mount

The designed VTX mount can fit anything that is the same size as FX798T and Hyperion 25mw.

The dedicated antenna protector fits nicely into the mount, and doesn’t fall out in crashes. It reduces the chances of damaging your VTX and antenna by crash impact.

The camera mount is then perfectly fixed on top of the main body with zip ties.

Zip Tie

You might be concerned by the amount of zip tie I used. Don’t worry I did the math :) I chose the lightest zip tie possible (1.6mm), and each zip tie after cutting away the tail, only weights 0.035g in average. For the number of zip tie I used which is 11, the total weight is only 0.385g.

Example Build Logs

Here is an example build with Micro Scisky FC.

Here is an example build with Brushed EVO F3 FC.

How is Whoopee compared to other Ducted Micro frames?

I have seen quite a few other Ducted micro frames for 8.5mm brushed motors, but most of them are either:

- too heavy

- too difficult to print

- not easy to setup

- easy to break

- doesn’t allow many FC options

You should see quite clearly the differences.

Oskie VS Whoopee

The Oskie micro frame is super light weight and durable (at 6.4g), but it doesn’t have any propeller protection like the Whoopee, so props do break or go missing sometimes when you crash.

The Whoopee and Oskie frames are created for different purposes. Oskie is more suited for outdoor and high speed racing, while the Whoopee is design mainly for indoor flights around lots of obstacles.

Discussion on Forum

If you have any question, ideas or comments please leave them on this forum thread.

Printing the Frame

I don’t intend to get rich with this design, so I am making the print files available to everyone. Feel free to print it yourself. It’s a very hard thing to print and I probably have 30% fail rate myself. I am running a Ultimaker 2+ with Cura. I tried many settings and I have good result with “Normal” printing profile (it takes almost 3 hours to print). It would be even better to go with “Fine” if you can.

Use “Support” “Everywhere”, I prefer the Line type. Infill density 100%.

STL Files Download on Thingiverse

Purchasing the Frame

Availability: No Longer In Stock

If you don’t have a 3D printer and want to support my design, you can purchase the frame directly from me. It’s not an easy print, takes nearly 3 hours, plus another 30 mins of cleaning up manually by myself.

The frame kit includes:

15 x 1.6mm zip ties4cm of Heatshrink tubes for the motors (1cm per motor)2 x Double side foam tapes for FCWhoopee Frame

Frame colour is currently black. Default VTX mount has 10 degree tilt, if you need different angle please specify (available tilt angle: 10, 15)

Dispatched every Monday/Thursday, item should arrive within 2 working days within the UK, 7 working days worldwide. Please note that if you choose no tracking shipping method, I am not responsible if the item goes lost. However we are able to provide a full refund or resend the item if tracked shipping is selected (because we are covered by the courier).

35 comments

I made a big mistake printing 3 of these for my kids as a school science project. I have just printed and made my 20th today for their classmates.

On the 3D printing side I am using a Zortrx printer . I have tried HIPS, PLA, ABS and PETG. HIPS prints fine but doesn’t have a high enough tensile strength, I had shrinkage and warping problems with both ABS and PLA. PETG and the translucent version are the best in terms of strength and ease of printing. I print on a 0.14 resolution and a max infill; not that there is any infill.

PETG does make the frame about 20% heavier, average 11.5 to 12g however it still flies good and PETG has enough flexibility not to break in a crash

Great design Oscar

Any way to order one of these frames? This looks like it would be a fun introduction into micro quads.

sorry I’ve stopped selling them, it simply takes too much time :)

However you can ask a friend or 3Dprint shop to print one with the files I provided.

Really nice model.

I wish that you would share the source files. There are some improvements that I would make to this model to make it more sturdy (fillets at some crucially flimsy joints for example), and align some of the dimensions to a multiple of the extrusion width to provide stronger walls.

Also your model appears to have been tuned for your printer because the motor mounts are not 8.5mm, they are 8.2mm.

In the end I’ll probably draw this in solidworks from scratch, but I appreciate the thought leadership.

Did you measure it after printing? Because in my design I made the motor mount around 8.55-8.6mm. Maybe it shrinked a little bit on your prints?

The frame was beefier in my earlier revisions, but I found it to be unnecessary and too heavy for my liking.

Oscar, I’m having the same issue as Geekazoid, but when I went into CAD and measured your STL file it was indeed 8.6mm.

Seems I need to recalibrate my printer now :(

I guess I know what I’m doing over my Christmas vacation! One day soon I will put my original DIY printer to rest and buy a ready-to-use printer. Until then, the struggle continues. LOL

I remember it was 8.55mm something :)

filament plays a big parts when designing precise measurement like this… some material shrinks more than others…

Hi Oscar, I just came back here to see if you replied.

Yes I measured the print and the model. I’m printing in PLA+ so shrinkage isn’t an issue.

I just print this right side up with support so it looks clean. Takes longer but I don’t care.

Hi Oscar,

I ordered one of your frames with tracking, I was wondering how I could get the tracking number?

Hi Justin, I think I emailed you on the day it was posted :) let me know if you still have any questions.

Hi Oscar, You didn’t talk about radio receiver.. What is the compatible size?

Will it fit in there:

banggood.com/FLYSKY-Ultra-Miniature-PPM-Signal-Output-8CH-Receiver-For-Multicopter-p-988175.html

yes in terms of size and weight that should work fine.

Do you think this frame needs a cross support similar to tiny whoop supports? If yes can you provide that as well with the frame when you are able to start producing them again?

Hi oscaryour kit

I think to order your Kit whoope, when it will be available

what is the price?

thanks

alain

hopefully by the end of this week, please check again after the 27th, on this page :)

Hey Oscar,

Love the frame! What size propellers does this take?

Thanks!

Hubsan and Ladybird props :)

Just printed this on my I3 MK2 and it came out beautifully.

I’d like to PayPal you the money for a frame

Let me know

Travis

[email protected]

please purchase using the button provided on this page :) thanks

do you consider designing a even smaller ones to replace the tiny whoop?

I don’t think it can replace the Tiny Whoop, both of them perform differently and have their own advantages.

the Whoopee can’t go any smaller, unless we can find a smaller FC (like the Furious NUKE).

But still it’s going to be larger than the Tiny whoop because of the larger propellers.

Lady bird props seem to work decent cut down to 46mm http://i.imgur.com/YKETtWSl.jpg on this small 77mm, 8.5 brushless motor frame I have; http://i.imgur.com/iKohk4Zl.jpg. It flies strong for weighing 54.1g and agile. It is a small example that the props do work cut down smaller.

Please decide to do some smaller prototypes sized between the tiny whoop and your Whoopee, I would like to test one. :)

Quadrop, RCG

thanks for the tip, i will try that out :)

I’m confused by the motor install, I saw your Brushed EVO F3.

The motors that are installed are they in the correct factory rotation?

I got the Chaoli ones which states;

1. Clockwise (Red Blue)

2. Counter Clockwise (White Black)

In Cleanflight or Betaflight order:

Rear Right (Motor 1)

Front Right (Motor 2)

Rear Left (Motor 3)

Front Left (Motor 4)

When I see picnic quads the Chaoli motor wire color codes are direct opposite of what you installed, so I’m confused.

Are the brush installed in favor of a certain direction or it don’t matter?

Take Motor 1 for example, you installed on the Brushed EVO F3 with the “Blue Red” (clockwise factory motor).

I really don’t know what to do now as to which motors goes where?

Would be nice if you can help me understand.

The colour of the wires are not universal, so they could be different from brand to brand. I would say stick to what is on the manual.

I was using Banggood motors on the Scisky build, MMW Dark motors on the EVO build.

My brother, have you considered using TFU as the material ? It’s unbreakable and perfect for indoor flying as its softer, so you can crash however you like.

you mean TPU? TPU is a bit too flexible for frame IMO, I think stiffness is also important.

Hi Oscar,

I love the frame you built and the writeup. I’ve been running a similar setup on a different frame, but I have been having difficulties with obstacles when competing at tiny whoop races. I’m heavily considering switching to your frame.

How light can you make a build using this frame and the MMW dark edition -17 motors, micro frsky RX, lulfro, tinywhoop cam + vtx combo, MMW 480mah batteries & 18 AWG JST battery lead?

Right now my build is at 51.90g all in. If you think it’s possible to get to that weight, or lower i’ll buy right now.

Also – how does the Lulfro compare to the Brushed EVO F3 & Multiflite Pico? I’m curious to know how these boards compare in terms of FET amp rating and processing speed/capacity. I tried to look up the comparison here: https://oscarliang.com/fpv-micro-quad-beef-board/ and here: https://oscarliang.com/brushed-micro-quad-parts-list/ but the multiflite pico and brushed evo f3 were not listed.

Would love to learn more from you about this!

Thank you for your awesome contributions to the community!

can you weight all of your electroincs? my frame is around 12-13g including FC plate and VTX mount.

My build without battery is 44g with battery I think it’s about 57g (400mah).

this is not a light weight frame, and it takes off at around 55% throttle, but that doesn’t seem to affect flight time too much maybe because of the ducts.

Hi Oscar,

Thanks for your reply. I can check it out and see how it works.

What’s your thought on comparing the lufro to the EVo f3 and multiflite pico? Have you tested the FETs to see how they differ, and tested the processing capacity of each?

I want to know what the best one is

Lulfro is a great board! I would recommend that if you have the budget.

I haven’t received the brushed EVO F3 yet.

I haven’t got the latest multiflite pico, only a test board. it’s also great, but it’s got so many connectors built-in it gets a bit heavy. size is the similar to the Lulfro though.

Only concern with FET normally is how much current they can handle, but so far I haven’t had any problem with any of these boards.

Very nice frame. Do you have any problems with breaking arms that supports motor mountings? It is a very common in original Iductrix. I needed to reinforce the frame by adding a square made of 1.8mm carbon rods on the bottom.

Do you send this frames to UK?

Completely agree with your assessment of the whoop. It’s the first generation iphone of ducted brushed micro quads. You want to wait a couple of generations before it really works.

Bought 2 without even a moment’s thought.

Some recommendations I can already see:

– a version for the hubsan tri would be nice, similar power less width. More tiny whoopy

– too much clearance between the motors and the ducts, though I don’t know if this is solvable in this reality

thanks :)

– some testers of those triblades said they are no good, badly balanced, less flight time and even less power than dual blade.

– The clearance is because of the FC mounting, that’s why it’s compatible with so many FC