In this comprehensive tutorial, I’ll walk you through the process of building an FPV drone from scratch, providing detailed guidance for both analogue and digital FPV systems. We’ll cover everything from selecting the right components, to wiring and assembly, and even share insider tips and tricks to ensure you have a reliable and enjoyable FPV drone experience.

Table of Contents

Can Beginner Build FPV Drones?

Without a doubt, beginners can absolutely build FPV drones even without any experience!

Sure, it might be tempting to simply purchase a ready-made drone off the shelf, but where’s the fun in that? By assembling your very own drone from scratch, you’ll not only gain valuable knowledge about how each component fits together, but you’ll also be better equipped to repair it should anything go wrong.

Now, I won’t sugar coat it – building your first FPV drone is going to be challenging, and it might take hours or even days to complete. But fear not! Along the way, you’ll have the opportunity to seek guidance from seasoned pilots online or, if you’re feeling adventurous, navigate the learning process through trial and error. In the end, the sense of accomplishment and the skills you acquire will make the journey incredibly rewarding. So, let’s dive in and embrace the challenges ahead!

Mastering the Basics

Before we embark on this exciting tutorial, it’s essential to familiarize yourself with the basics of a quadcopter. To start, ensure you have a basic understanding of what an FPV drone entails by checking out our introductory guide:Getting Started with FPV Drone.

As you delve deeper into the world of FPV drones, you may encounter various acronyms and technical jargon. Don’t let these terms intimidate you! Simply refer to our comprehensive glossary: Decoding Acronyms and Technical Terms in FPV.

With these resources at your fingertips, you’ll be well on your way to becoming an FPV drone aficionado in no time.

Parts List

In this tutorial, we’ll be using the following parts to guide you through the FPV drone building process. I just want to make it clear that the links provided are affiliate links. Making a purchase through these links won’t incur any additional costs for you, but it will provide me with a small commission. This support helps keep this blog running and allows me to continue sharing my passion for FPV drones with you.

If you have a small budget, here is a list of the cheapest 5″ drone parts in 2023.

If you want more options, here is a list of parts that I recommend.

Analog Build |

||

| Frame | TBS Source One V5 | GetFPV | Amazon | AliExpress |

| FC / ESC | Speedybee F405 V3 + BLS 50A 4in1 ESC | GetFPV | RDQ | Amazon | AliEx |

| Motors | 4x iFlight Xing2 2207 1855KV | Banggood | GetFPV | Amazon |

| Propellers | 4x HQ 5×4.3×3 V2S | RDQ | GetFPV | AliExpress |

| Receiver | Radiomaster RP1 ExpressLRS | GetFPV | Banggood | RM |

| FPV Camera | Caddx Ratel 2 | Banggood | GetFPV | RDQ |

| VTX | Speedybee TX800 | RDQ | GetFPV | AliExpress |

| Misc. Part | Battery Strap (20x220mm) | Banggood | GetFPV | RDQ |

| Optional | Upgrade VTX Antenna | NewBeeDrone | RDQ |

DJI Build |

||

| Frame | TBS Source One (V5) | GetFPV | Amazon | AliExpress |

| FC / ESC | Speedybee F405 V3 + 50A 4in1 ESC | GetFPV | Speedybee | Amz | AE |

| Motors | 4x iFlight Xing2 2207 1855KV | Banggood | GetFPV | Amazon |

| Propellers | 4x HQ 5×4.3×3 V2S | RDQ | GetFPV | AliExpress |

| Receiver | Radiomaster RP1 ExpressLRS | GetFPV | Banggood | RM |

| FPV Setup | Runcam Link + Runcam Wasp (DJI System) | AliExpress | GetFPV | RDQ |

| Misc Part | Battery Strap (20x220mm) | Banggood | GetFPV | RDQ |

Essential Tools and Supplies

To successfully build your FPV drone, you’ll need the following tools and supplies. Some of these items may already be in your toolkit, while others can be easily found online or at your local hardware store:

- Soldering Iron and solder

- Hex screwdrivers set (Buy from Amazon)

- A small Phillips head screwdriver (Buy from Amazon)

- A pair of scissors for stripping and cutting wires

- Electrical tape (Buy from Amazon)

- 3M double sided foam tape (Buy from Amazon)

- Digital multimeter (Buy from Amazon | Banggood)

- A collection of 2mm wide zip ties (ideally 15cm or longer, buy from Amazon)

- Cloth tape (15mm width is ideal, perfect for wrapping motor wires, though you may substitute with electrical tape, buy from Amazon)

For those truly passionate about the hobby, here’s a comprehensive list of tools that you may find invaluable on your FPV drone-building journey.

The Frame

A frame is a sturdy structure that holds all the components.

For this tutorial, I’ve selected the latest Source One V5 frame, an excellent choice due to its affordability and open-source nature. The design has evolved over time, thanks to constant updates from the dedicated community, ensuring compatibility with current hardware, and optimizing performance and usability. Check out my detailed review of the TBS Source One V5 frame here.

Another great advantage of the Source One is the plethora of free 3D printing designs available on Thingiverse. These designs allow you to enhance and customize your FPV drone build even further.

FC and ESC

Selecting an “FC stack” – which includes both a flight controller board and a 4in1 ESC board – is a wise choice for beginners. With minimal soldering required, these stacks are often plug-and-play, making assembly smooth and straightforward.

For this tutorial, I’ve opted for the Speedybee F405 V3 stack, one of the best value stacks on the market in 2022 and 2023. It boasts an array of features, including built-in Bluetooth for Betaflight configuration via your phone, and much more! Check out my in-depth review of the Speedybee F405 V3 here.

If, for some reason, you’re unable to acquire the Speedybee F405 V3, don’t fret! Here are my other flight controller recommendations to suit your needs.

Motors

While popular motors of similar sizes often have comparable performance, the key differentiator typically lies in their build quality. For a 5″ FPV drone, motor sizes such as 2306, 2207, and 2208 are all viable options – here’s an explanation of why I’ve selected 2207 for this tutorial.

Another important factor to consider is motor KV, which is determined by battery voltage. For 6S LiPo, KV values ranging from 1600 to 1900 are common, with higher KV values providing more aggressive and power-hungry performance. In this build, we’re using 1855KV motors, as I plan to use 6S LiPo battery. While 4S builds are also popular, I personally prefer 6S over 4S for these reasons.

In this post, you’ll find a list of other motors I recommend – each of which delivers impressive performance.

FPV Setup

Currently, the two most popular FPV systems are analog and DJI. In this tutorial, we’ll cover the installation and setup for both systems.

Keep in mind that there are other digital FPV systems available, such as HDZero and Walksnail Avatar. The wiring and setup for these systems are largely similar to DJI, so this tutorial remains applicable.

For the analog build, we’ll be using the Speedybee TX800, an affordable and high-performance VTX that easily mounts in the Source One frame. If it’s unavailable to you, here are other VTX options I recommend.

For the DJI build, our choice is the Runcam Link VTX and Wasp Camera combo.

There’s a wide variety of DJI-compatible cameras on the market, each with its own pros and cons. In short, if you’re after the best daytime image quality, I’d recommend the Nebula Pro, which has image quality almost identical to the original DJI camera. However, it’s often out of stock and performs poorly in low-light conditions. For better low-light performance, the Caddx Polar is an excellent choice, but it lacks a low latency mode (120FPS). The Runcam Wasp offers a balanced option with decent image quality, low-light performance, and the ability to operate in 120FPS low latency mode. While it isn’t a perfect camera, it boasts features that are, in my opinion, not deal breakers. Make sure to read my review to make an informed decision.

Radio Receiver

Your choice of radio transmitter dictates the type of receiver (RX) you can use. If you followed my radio recommendations, your radio should support ExpressLRS, which is currently my top choice for a radio link in 2023. ExpressLRS is affordable, high-performance, and incredibly reliable! Read my article on why I love ExpressLRS to learn more.

Numerous manufacturers produce receivers and transmitter modules for ExpressLRS. You can choose any of these, and as long as they’re ExpressLRS, they’ll work together. For this tutorial, I’ve selected the Radiomaster RP1 receiver, which I’ve been using for several months now. It delivers excellent performance and has consistently remained in stock.

To help you set up ExpressLRS, I’ve put together a step-by-step tutorial.

Other Equipment

To fly a quadcopter in FPV, you’ll need the following accessories. Take a look at my everyday gear for inspiration. Here is a summary:

- Radio Transmitter: A radio transmitter is essential for controlling your drone. In 2023, I recommend the Radiomaster Boxer (review) or TX16S MKII (review), as they both offer excellent value for money. Check out the Radio Transmitter Buyer’s Guide for more options.

- Analog FPV System: FPV goggles allow you to watch real-time video from your drone. For guidance, consult my FPV Goggles Buyer’s Guide. The top-of-the-line analog FPV goggles at the moment (Nov 2022) are the HDZero FPV Goggles (review), as they also support multiple FPV systems. If you just want to fly analog and save money, the next top choice would be the Skyzone SKY04X. If you’re on a tighter budget, the Skyzone Cobra X (review) offers a fantastic value as an affordable “box goggles” option.

- DJI FPV System: To use the DJI FPV System, you’ll need a pair of DJI FPV Goggles (review). Go for the V2 as they also support the latest DJI O3 Air Unit as well as analog.

- LiPo Batteries: For this build, 6S 1000mAh-1300mAh LiPo batteries would be ideal. Check out my LiPo Recommendations here. Be sure to familiarize yourself with LiPo batteries using this Battery Buyer’s Guide, as improper handling can be dangerous.

- Battery Charger: Lastly, you’ll need a battery charger. I’ve put together a list of recommended LiPo chargers for your convenience. Make sure to read about how to choose LiPo chargers and power supplies.

For other FPV Drone parts that I’ve tested and recommend, visit: https://oscarliang.com/tag/recommend/

Steps of Building FPV Drone

Click the link will take you to the section in this article:

- 1. Frame Assembly

- 2. Installing Motors

- 3. Wiring Diagrams

- 4. Installing ESC

- 5. Testing ESC and Motors

- 6. Receiver Setup

- 7. Installing Analog FPV Setup

- 8. Installing DJI FPV Setup

- 9. Finishing Off

- 10. Using 3D Printed Parts

- 11. Setting Up Betaflight

- 12. Tuning

- 13. Learning How to Fly

1. Frame Assembly

Before building, it’s a good idea to prepare the frame, although this step is optional:

- Sand down the sharp edges on carbon fibre pieces, particularly on the outer side of the arms and plates. Sharp edges could cut your wires and battery strap in a crash. Chamfered edges can also help reduce the likelihood of carbon fibre sheet delamination in crashes.

- Wash all carbon fibre parts in soapy water to remove any remaining carbon dust from cutting, drilling, and sanding (keep in mind that carbon fibre is conductive). Then, dry the parts thoroughly with a towel.

To assemble the frame, start by positioning the arms and arm lock on top of the front bottom plate.

Next, place the rear bottom plate (which has push nuts) on top of the arms, and fasten it with screws from the bottom. Lastly, install the eight aluminium standoffs, but be mindful of their different heights – the four front standoffs are longer.

2. Installing Motors

Now, it’s time to mount the four motors to the arms. It’s recommended to use threadlock on the motor screws, as vibrations from the motors can cause screws to loosen over time. Fortunately, the screws that come with the Xing2 motors already have threadlock applied, so there’s no need for additional application.

The arms are 6mm thick, making the 8mm screws the perfect length. There’s no need to use washers.

If you’re using ordinary screws, be sure to get some Loctite (thread locker). Opt for the blue liquid type, as the red liquid type is designed for permanent use and can make removing the screws later quite difficult.

Lastly, ensure the motor screws aren’t too long and touching the motor winding. If you’re uncertain about the screw length, follow this guide on how to check if your motor screws are too long.

3. Wiring Diagrams

Before proceeding, it’s a good idea to create a wiring diagram on a piece of paper outlining how to connect all the components. If you’re using the components I recommended, here are connection diagrams you can follow.

For the Analog build:

For the DJI build:

Before soldering any wires, you can “dry fit” all the components in the frame. This process allows you to gauge wire lengths, determine component placement, and identify any potential spacing issues.

Analog build:

DJI build:

4. Installing ESC

Begin by replacing the four shorter screws in the frame with the long M3 30mm bolts that come with the Speedybee F405 V3 stack. Avoid using nylon standoffs for installing FC, ESC and VTX, they break easily in crashes. Use metal bolts instead.

Use metal bolts for installing stack (with a metal nut at the botttom), it reduces vibration and wobble, makes the drone fly better and easier to tune.

Slide the 4in1 ESC and FC boards onto the four long screws, ensuring the ESC board’s power pads face backward and the motor solder pads face up. The front of the frame is identifiable by the cut-outs for the camera mounting plates.

Inspect the bottom of the ESC to ensure it’s not touching the frame. Additionally, check for any contact between the ESC and FC.

Next, you’ll do some soldering. If you’re new to soldering, refer to the tutorial “How to Solder for Beginners“.

Determine the required motor wire lengths, leaving a little slack, and cut them accordingly. Secure the motor wires on the arms with cloth tape or electrical tape.

Some people like to use braided mesh tubes over the motor wires for protection/aesthetics purposes. Personally I don’t use them, they are a pain to install and they don’t really provide much protection or benefits.

Then, strip about 2mm off the tip of the wires and tin the ends.

Using the trimmed off motor wires, solder two of them to the input power of the ESC (ideally on the bottom side). Mark the positive wires with a piece of tape to solder the capacitor to later. You can also use any 20AWG or 22AWG silicone electrical wires.

Tin all the solder pads on the 4in1 ESC. To prevent solder from accidentally dropping onto the components and causing electrical shorts, cover the areas of the board where you’re not soldering with tape, such as electrical tape, kapton tape, or masking tape.

Solder the motor wires onto the ESC. Don’t worry about wire order and motor direction yet; you can change this later in the software. If you have the skills, you could try to solder motor wires side way, make it nicer to grab the quad.

Solder the XT60 power lead to the power pads on the ESC, making sure to maintain the correct polarity (positive and negative). This step may be challenging due to the amount of heat required to melt the solder on the large copper pads. Be patient and use a higher temperature on your iron.

Soldering Tips:

- Use a good amount of solder and solder flux (solder paste) for the large pads, ensuring the solder joints are shiny and full. If you can see the wire strands, you haven’t applied enough solder.

- Apply more flux if the solder “sticks” to the tip when you remove it from the joint.

- Feel free to use a high temperature when soldering large solder pads, but be quick and avoid overheating the pads for too long. Use 450°C (840°F) for motor wires and XT60, and 380°C for signal wires.

Now solder the 1500uF capacitor that comes with the Speedybee stack. Bend and shorten the legs with pliers, then tin them with solder.

Apply a small piece of double-sided tape to the bottom of the capacitor.

Solder the capacitor to the wires connected to the ESC power pads earlier, being mindful of the polarity. The side with yellow marking is the negative side of the capacitor.

A capacitor is used to reduce voltage spikes and electrical noise generated by the ESC and motors. It can also help when bent props create more noise. To learn more about why adding an extra capacitor to FPV drones is useful, see this post.

Finally, connect the FC to the ESC using the provided 8-pin ribbon cable. When installing the flight controller on top of the 4in1 ESC, ensure the arrow on the FC points forward.

5. Testing ESC and Motors

Before plugging in a LiPo battery for the first time, ensure there are no electrical shorts. Using a multimeter in continuity mode, test the positive and negative terminals of the XT60 (or directly on the solder pads). If there is a short circuit, the multimeter will beep continuously. In this case, do not plug in the battery, as it may damage your components. Instead, troubleshoot and fix the issue that is causing the short circuit.

For more information on using a multimeter to test your drone, check out this tutorial.

Pro-Tip: A short beep followed by silence may occur when testing continuity due to capacitors charging. This is normal and shouldn’t cause concern. As long as it stops beeping after a second or two you should be fine.

Use a smoke stopper when plugging in a battery for the first time. While not mandatory, it’s a recommended investment to avoid damaging components.

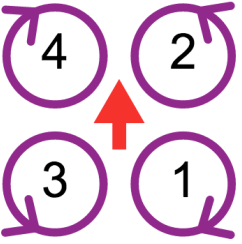

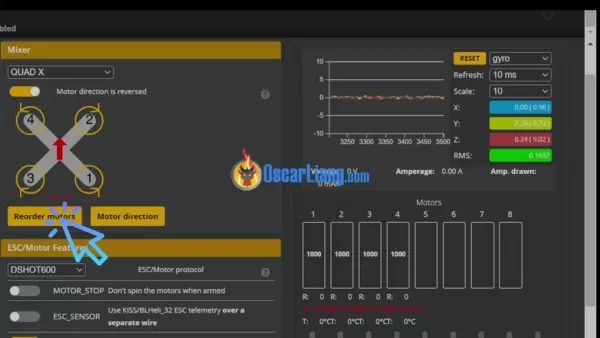

Do not install propellers yet. To test the motors, plug in the battery and connect the USB cable to the flight controller. In the Motors tab of the Betaflight Configurator, spin up the motors one by one (move the slider to around 10%) and verify if they are spinning in the correct direction.

To reverse a motor spinning in the wrong direction, use the Betaflight Configurator (Motors tab) as explained here.

Also make sure the spinning motor number matches the diagram, e.g. motor #1 is the rear right, motor #2 is front right etc.

If the motor order is wrong you need to fix it using the “Reorder Motors” tool in the motors tab, and following the instructions. You can also fix it using CLI commands but it’s a lot more complicated, just use the tool :)

Troubleshooting tips:

- If motors aren’t spinning, ensure the battery is connected. And the ESC should beep as soon as you plug in the battery. Make sure the ESC is connected to the FC, and that the pin connections are correct.

- If all motors spin except for one, that particular ESC, motor, or the ESC signal from the FC might be faulty. To troubleshoot, swap the non-functioning motor with a working one on the same quad to determine if the issue lies with the ESC or motor.

For further assistance, ask in the forum: https://intofpv.com

6. Receiver Setup

To solder the RX to the FC, you’ll need your own 28AWG or 30AWG wires, as the RP1 does not come with them: https://oscarliang.com/wires-connectors/

Mount the RX in front of the FC using double-sided foam tape or a zip tie. You can mount it anywhere with enough space in the frame.

It’s best to keep the top of the FC clear of any wires, avoid running wires on top or next to the gyro which could cause vibration during flight.

Secure the RX antenna under the closest arm with zip ties and wrap the antenna wire with tape to prevent it from getting caught.

Bind the receiver to the radio (TX module) following the guide on setting up ExpressLRS. In the Betaflight configurator, apply these configurations:

- Go to the Ports tab and enable “Serial RX” for the UART connected to the receiver (UART2 in our example).

- In the Receiver tab, select “Serial (via UART)” in Receiver Mode and choose “CRSF” in Serial Receiver Provider.

After this, confirm that the receiver is working properly in the Receiver tab. The bars (channels) should move when you move the sticks on the radio. If the wrong channels are responding, try a different Channel Map such as “default (AETR)” or “TAER.”

Set up at least two switches on the radio (instructions) for arming and beeper. You might also want a third switch for flight mode (e.g., angle mode). Confirm that these switches work in the Receiver tab, with AUX1 and AUX2 responding when you flip them.

For any questions, post in the forum: https://intoFPV.com

7. Installing Analog FPV Setup

This section is for the analog build. If you’re using the DJI FPV system, skip to the next section.

Install the camera between the side plates.

Place the camera inside the frame and cut the camera wires to length. Twist the wires to keep them tight.

Solder the camera wires to the FC: Red goes to 5V, black goes to GND, and yellow goes to CAM.

For installing the VTX, you could consider just use double sided tape and zip tie, instead of using standoffs. It’s easy, secure and weight saving if you don’t care how your quad look, just performing well.

Apply double-sided foam tape to the bottom of the VTX, ensuring that it covers any copper to prevent contact with the frame when mounted.

Insert 2mm zip ties through the mounting holes and tighten. Simultaneously tighten down the battery leads.

This is how it looks from the bottom of the frame.

Solder the VTX cable to the FC and make sure it doesn’t dangle around.

Strap the VTX antenna to the standoff.

To setup the VTX in Betaflight, go to the Ports tab and, for the UART that you have connected the IRC pad to, select IRC Tramp under Peripherals.

Copy the VTX Table snippet below into the CLI for the Speedybee TX800. This will enable you to change VTX settings in the OSD menu.

# vtxtable

vtxtable bands 5

vtxtable channels 8

vtxtable band 1 BOSCAM_A A CUSTOM 5865 5845 5825 5805 5785 5765 5745 5725

vtxtable band 2 BOSCAM_B B CUSTOM 5733 5752 5771 5790 5809 5828 5847 5866

vtxtable band 3 BOSCAM_E E CUSTOM 5705 5685 5665 0 5885 5905 0 0

vtxtable band 4 FATSHARK F CUSTOM 5740 5760 5780 5800 5820 5840 5860 5880

vtxtable band 5 RACEBAND R CUSTOM 5658 5695 5732 5769 5806 5843 5880 5917

vtxtable powerlevels 5

vtxtable powervalues 25 200 400 600 600

vtxtable powerlabels 25 200 400 800 800

save

8. Installing DJI FPV Setup

Follow these steps to install the Runcam Link and Wasp camera in the DJI build:

Mount the Wasp camera between the side plates and install it inside the frame, similar to the process in the analog build.

Take the DJI Air Unit cable that comes with the FC, cut the ends, and solder it to the Vista. Here’s the pinout of the Vista:

You won’t connect the SBUS and GND pads in the Vista, so cut those two wires off in the cable.

Apply double-sided foam tape to the bottom of the Runcam Link (Vista).

Optionally, run the camera cable beneath the 4-in-1 ESC board for a cleaner build. You can disconnect the camera cable from the video transmitter if necessary.

Install the Vista in the frame using 2mm zip ties (ideally 15mm or longer), and strap the VTX antenna to the standoff as shown:

In order to have OSD for displaying battery level and other flight information on screen, you need to configure Betaflight.

To configure Betaflight for OSD (on-screen display) to show battery level and other flight information. This page explains how to do it in detail. To sum it up, in Betaflight configurator, you need to:

- In Ports tab, UART1 enable “Configuration/MSP“

- In Configuration tab, under Other Features, enable OSD

- Inside your DJI Goggles, go to Settings, Display and turn on Custom OSD

That’s it!

As a final check, power the drone from a LiPo battery again using a smoke stopper to ensure everything works properly before moving on to the next step.

9. Finishing Off

To complete your drone build, follow these steps.

Secure FC with nylon nuts, fasten with your hands to avoid over-tightening, they should just touch the rubber grommet. Compressed grommets reduce vibration damping and defeat the purpose of soft mounting.

Strap the capacitor to the camera plates using a zip tie.

Install the top plate and thread a battery strap under and through it. The Source One V5 comes with a rubbery battery pad that works well, but if you prefer a top-notch option, consider the Ummagrip battery pad. It’s sticky, washable, and its thickness keeps your battery safely away from the bolts.

The weights of the finished drone are as follows:

- Drone: 360g

- Drone + 6S 1100mAh LiPo: 560g

- Drone + 6S 1100mAh LiPo + GoPro 7: 680g

When installing the propellers, pay attention to the different rotations—CW (clockwise) and CCW (counter-clockwise). Ensure they are installed on the correct motors; otherwise, your quad may not take off or could flip over when trying to.

Use M5 nylon lock nuts to hold the propellers securely on the motor. Tightening might be challenging at first but will become easier over time. Avoid overtightening to prevent prop hub shattering. Tighten just enough so the prop can’t move when you try to rotate it with your hand while holding the motor bell.

A dedicated prop nut tool can speed up prop changes.

When mounting the battery (and GoPro), ensure the COG (center of gravity) is as close to the drone’s center as possible. To check if the battery is placed correctly, grab the middle of the top plate with two fingers and see if the quad stays level.

It’s essential to maintain the COG at the center of the four motors. If the quad is front-heavy, the front motors will work harder than the rear motors to maintain a level position, negatively impacting flight performance.

And we are ready for a test flight!

Here’s the DJI build:

10. Using 3D Printed Parts

For a cleaner, sleeker, and more durable build, consider using 3D printed parts. You can find various designs online by searching for “Source One V5” on Thingiverse.com. Parts for other frames might also work on the Source One. One recommended source for 3D printed parts is https://3dprintsfpv.co.uk/. If you can’t find the parts you want in their shop, send them a message with the Thingiverse link and the filament color you want, I am sure they are happy to help.

Here are some good ones I found:

- My designs for the V4, but some parts works for V5 too: https://www.thingiverse.com/thing:4844808

- Arm protector and bumper: https://www.thingiverse.com/thing:4706164

- GoPro 5-7 Mount: https://www.thingiverse.com/thing:5416938

Front bumpers and arm protectors provide excellent protection for your frame in crashes. For these arm protectors, you may need longer motor screws, such as M3 10mm.

In the analog build, using a 3D printed antenna mount allows you to utilize the MMCX to SMA extension cable that comes with the TX800 and upgrade the VTX antenna to a circular polarized one for better signal quality.

3D printed parts can also be used to mount the camera and capacitor.

The DJI build with 3D printed parts offers an improved appearance:

A 3D printed mount holds the Vista antenna at a more optimal angle for flying.

11. Setting Up Betaflight

To set up Betaflight for your first flight, follow the instructions in this guide: “how to setup Betaflight for the first time“.

12. Tuning

Tuning your quadcopter involves adjusting it to fly and behave the way you want. Betaflight has come a long way; you don’t have to tune your quad, and it will likely fly just fine with stock settings. However, if you’re serious about performance, there’s more to learn!

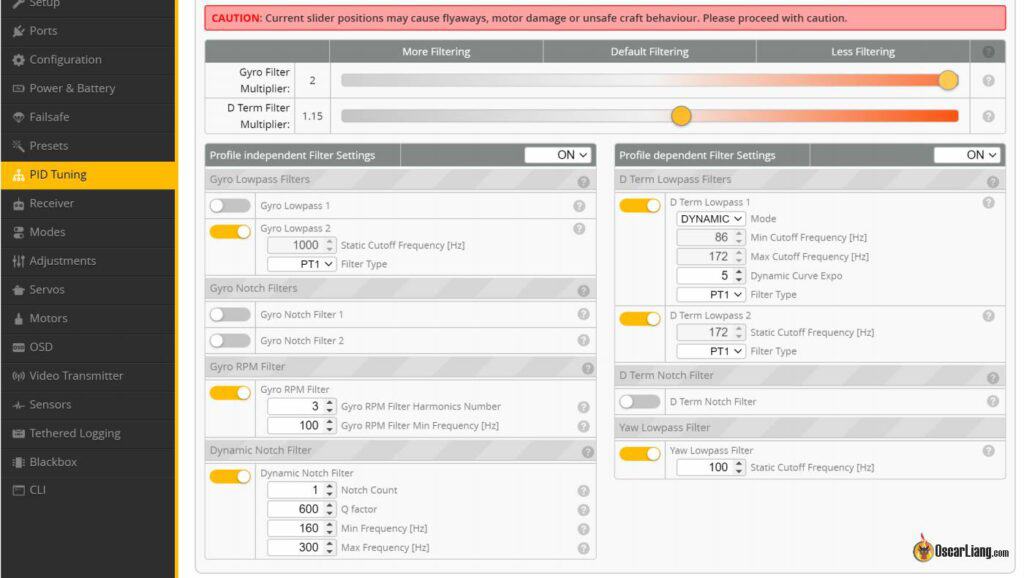

For most people, tuning a mini quad involves adjusting these settings:

If you don’t know how to use Blackbox, this is how to tune your FPV drone in 10 simple steps. If you’re familiar with Blackbox, check out this in-depth guide on tuning filters and PID.

The following is my PID and Filter tune for this build, but it might not work well for you if you’re using different components. It’s an aggressive tune, so perform a short test flight and check your motor temperature before using it. It’s highly recommended to tune your build from scratch following this guide.

My rates for freestyle are (Actual Rate):

- Center Sensitivity 180

- Max Rate 750

- Expo 0.56

13. Learning How to Fly

If you have little to no experience flying a mini quad, consider checking out these tutorials to get started:

- Practice with FPV simulators

- Tips and Exercises to learn FPV flying

- Finding FPV flying difficult? Here are some advice from different pilots

If you have any questions, feel free to ask in the comments.

You can check my past build guides from 2020 and 2018:

- 2020 (DJI): https://drive.google.com/file/d/11-QBBVgNaPU-qeGUABUy_Np6zEWEFSn1/view?usp=share_link

- 2020 (4in1 ESC + analog): https://drive.google.com/file/d/1dWlCwGVU8NZAL00of8RBshyjXov2LDDW/view?usp=share_link

- 2018 (single ESC + analog): https://drive.google.com/file/d/1CvMcbZd7Wo2KRcxXvyaJ8WZrsAD9q0Li/view?usp=share_link

Improvements and Upgrades

Once you’ve mastered the basics of building and flying your FPV drone, you may consider making some improvements and upgrades to enhance its performance. Here’s a list of potential upgrades and improvements you can make:

- Flash Bluejay firmware to the ESC: You’ll need to choose between the 24kHz or 48kHz versions. The 24kHz version provides better responsiveness and torque, while the 48kHz version offers smoother flight with slightly less torque. In Betaflight, enable bi-directional Dshot, which allows you to turn on RPM filter, which is one of the best filters available.

- Use 3D printed parts: If you haven’t already, consider using 3D printed parts for improved durability and usability.

- If you have an analog build, consider upgrading the VTX antenna to a circular polarized one. The dipole antenna that comes with the TX800 is ok, but not the best.

- Properly tune your PID and Filter.

- Reverse Motor Direction (props out), so it’s less likely to get caught by branches, also keeps your camera lens clean from grass juice.

- If you have the DJI build, consider performing the root hack to get full OSD support.

These upgrades and improvements will help you get the most out of your FPV drone and enhance your overall flying experience. Remember that as you grow in skill and knowledge, there are always new techniques and technologies to explore in the world of FPV drones.

53 comments

Hi, I used your guides to build a killer drone. They are all so good.

Ware I am stuck at, Oscar is what would I enter in the CLI in Betaflight for the VTX TX800 Ultra I want to be able to use the 1.6W in the OSD?

Absolutely amazing guide! I’m going to copy the majority of this build! My only question is do you think there’s a way to keep the capacitor mounted in the back of the quad? It looks like there is some room around the vtx area. Just curious!

Hey Oscar, just wanted to say thanks for putting all this information out there, your website was my go to when I recently found out about the hobby.

I copied about 90% of the analog build and I’m having a blast, I’m finally starting to be confident to move like I do in simulators, I hit my first powerloop yesterday!

Hey Oscar, just wanted to thank you so much for this tutorial. Was my first 5″ drone and I’ve had an absolute blast with it as a beginner pilot. I made a YT video going over the parts/build process to first flight and linked all your info.

https://youtu.be/_-fTIqS6Oiw?si=UR-4pEPigkM8Ejnw

Thanks again! Tim.

Hey Oscar – I’m about to try this exact build (digital version) for my first build! Thanks so much for the tutorial. One question – I only have the DJI controller 2, will I be able to use that controller with the vista and just not bother about soldering the ELRS receiver? It does say that you can do that on the runcam website but just wanted to be sure.

I would like to swap over to ELRS eventually but for now I’d rather save the extra money and use my DJI controller.

Thanks again,

Tim.

I am not entirely sure as I don’t have the DJI Controller 2, but according to this compatibility chart it looks like it’s not compatible with the Vista: https://oscarliang.com/dji-o3-air-unit-fpv-goggles-2/#Compatibility

Hi,

This is a great guide. I was wondering if you had any suggestions to maximize the flight time for this build (like, 20 min per charge). I just like to enjoy the sights and don’t really need a super agile racing drone. I’m thinking of using the Digital DJI build but with the new O3 unit like others here have suggested. For this case, would it be better to:

Swap out the 6S LiPo battery with a 6S Li-ion? And if so, is there a good mAh range to consider?

Reduce the kV of the motors to something like 500 kV to 900 kV? Would that make it underpowered? Not sure what the sweet spot would be.

Maybe slightly different propellers? Larger ones might get more lift but there’s only so much you can fit on a 5″ frame.

And could I keep all of the other components the same? I.e. same FC & ESC Stack? The SpeedyBee F405 V4 looks pretty good as an upgrade from the V3.

I have a guide on extending flight time here: https://oscarliang.com/improve-fpv-drone-flight-time-efficiency/

Do I need to use Receiver rp1elrs if I want to use same build but with dji o3 ?

No you can just use the o3 alone :)

Hi Oscar! great tutorial, however when I plug my drone into my PC the VTX does not light up. Is it faulty or could it be my soldering job?

The VTX only gets power when you plug in the battery. The USB connection to the FC won’t power the VTX.

Is the instalation of dji o3 is similar like you did it here with wasp cam ? Considering everything else is the same

Not really it’s more complicated to installed in this frame. But You could probably just double sided tape it down and zip tie it to the frame. However for the camera, you will need some sort of 3D printed adapter because the lens is too big to fit inside the frame.

Wonderful stuff!

Have you considered hands -on training? Or are you already doing physical training or online? There could be some good business for you , if you are interested. Thanks a alot.

I am not doing hand on training currently, but if there’s an opportunity I would definitely consider it :)

Will this frame be compatable with dji o3 air unit ?

Yes but you need an 3D printed adapter to mount the camera as it sticks out in the front

Could you suggest something where I should look for ?

Hey Oscar, this is probably a noob question, but I’ll ask it anyway. I’m going to build my first drone, will be following your amazing tutorial, but I am going to use Walksnail Avatar for fpv. Can you recommend a camera will be a good choice for Walksnail? Don’t really care about image quality as far as it’s not analog :)

Thank you!

If you mostly fly during the day, I think the V2 camera is a great option. For low light, the Pro is the best option.

For budget option the new V3 nano kit is also worth considering though the image is not as good as the other two cams.

Hello, the tutorial and everything looks very special and great and everything. but how do i fly it? i mean with what controller? how do i connect the controller? and gow to i get the video that the camera is recording, and mainly how do i connect the fpv it self indp a vr goggles or a phone???

Hey Oscar, Thank you so much for this guide. This is my first fpv drone and just flying around has been a blast. I was sent the dji goggles 2 by mistake when I ordered the v2 goggles. With the goggles 2 I can’t seem to get the osd to work which makes flying a little worrisome as I can’t see the battery voltage. Is there a fix or workaround for the goggles 2 or do I just need to wait until there is more aftermarket support available for them?

Betaflight OSD is fully supported with the Goggles 2, including drone battery voltage. Take a look at the setup guide if you haven’t already: https://oscarliang.com/dji-o3-air-unit-fpv-goggles-2/#OSD

It says on their website that it works with the OG DJI controller – praying it works with the DJI C2. Otherwise happy to switch over to ELRS anyway. Thanks Oscar, looking forward to doing this for my first build and appreciate the tutorial.

Hi Oscar! Love your guides, helped me a ton getting into FPV and setting up my first quad.

So I built pretty much the same quad as you except for the frame and I use an DJI O3. But when I try to tune my quad like you did in the guide and enable RPM filtering with my Speedybee F405 V3 stack, I can’t figure out how to get my GYRO/FILTER/PID rates/hz down to 3200. I’ts pretty much always at 3250 to 3255 even with it’s stock config. So I can’t get it to less then 1% that you mention in your RPM filtering guide. Been trying to search the internet and get some answers but atm I’m just lost.

Would love to hear your response!

Keep up the awesome work!

Best regards Robin

In your case, I personally wouldn’t worry about it, the “1% difference” is just to give people a rough idea what they should be looking for. What we don’t want to see is the Gyro/PID drops below its target, which could be an indication that the FC processor is not keeping up. Take a look at your CPU load also, ensure it’s no higher than 75% (per Betaflight Developers’ recommendations), then you should be good to go. Do some test flight and make sure it’s working fine before further changes.

Thanks alot for your respone! My quad is flying great and I’m loving it! Thanks for what you do and keep doing it!

You’ve helped me alot with getting into FPV your guides and I’m learing so much!

Have a great day and keep up the awesome work!

Best regards Robin!

Hi there thank you for your detailed instructions on how to build a drone it’s very clear and awesome. However I would like to build a larger drone from say 7inch upto around 12inch. Maybe larger if possible. I would like it to be a long range drone aswell. Really I would like to create a monster of a drone high speed altitude and 3d capabilitys and I was wondering if you could help me a bit regarding your knowledge many thanks

tankk you for great toturial ….good job

Hey, after I plug in cable connecting ESC with FC and testing it with multimeter I have a beep. After disconnecting cable beep is gone. Can it be that connector cable is broken, or should I look somewhere else?

Hey, I found the issue – pin in the plug were touching

What’s cost of this kit?

Around 350-400$

Love all the detail! Thanks a ton! I got this put together a few weeks back and have been having a ball getting used to everything since it’s my very first FPV built. I did notice that the video quality coming to my DJI FPV goggles v2 is quite a bit pixelated. From 5m to 100m in a clear field the feed is no where near a clear picture. I’m honestly afraid to fly further since it’s so difficult to make out the image. Interestingly to me, it’s worse when I’m low to the ground and closer than when I am higher and just a bit further away.

Any suggestions, tips, tricks I should try would be greatly appreciated. I’m think that it might be interference and was thinking about resoldering the vtx with more twists in the line (I feel like I read somewhere that it’ll help shield from electrical interference).

your video link doesn’t sound normal and you should troubleshoot it.

– check all the antennas (on your VTX and Goggle) if they are attached properly.

– change to anther channel (avoid flying in channel 8 / channel P, that’s public channel)

– increase your output power if possible

– try flying somewhere else and see if that improves? maybe interference nearby.

Very helpfull

This artikell is detil and help me to learning about drone FPV.

Hlw,

Your work has been really helpful to me.

I am still waiting for the Speedybee f7v3 build.

Pls make it

Thanks in advance,

From india

I really like the presentation! Trouble is, I want to build something more like the Air 2s : lots of flight time, great pix ! Is it too hard ? Cliff

Oscar, thanks for the great tutorial! I have started the project following your tutorial but i want to use 4S batteries since I already have them from another hobby – could you please suggest what should be changed in the project? Which motors and propellers should be used according to your experience? Thanks in advance.

Simply get the 2755 KV version of the motor I suggested (you can pick on the product page I linked to), or any other 2207 motors with around 2400KV-2700KV should also work fine for 4S.

What is the range of this drone with the circular polarised antenna and the speedy bee vtx and something like the machine ev800d???

Very, very Good.

I am looking at building the DJI build what controller and fpv headset is needed thanks for the step by step and all the links

Thank you so much for creating this wonderful resource. I’m helping my son work through this to build his first FPV drone. Your instructions have been invaluable.

I would be grateful if you could explain this note from section 8:

We won’t connect the SBUS and GND pads in the Vista, so we can cut those two wires off in the cable.

How do you know not to connect these two wires? What would happen if we went ahead and connected them?

Thanks so much!

So the Vista has built-in receiver capability if you have a DJI FPV Remote to use with it, it outputs SBUS signal you can connect that to the flight controller.

But because we are using an external radio receiver, in this case an ExpressLRS receiver, we won’t need to connect the SBUS pad. You can connect them but they won’t do anything.

I recommend using an external radio receiver, the receiver in the Vista normally loses signal (giving you failsafe) before you lose video so it’s not really ideal.

Hey Oscar, great tutorial here. I just had one question. I want to install the caddx vista and presumably I would need to install the receiver as I am using the DJI remote v1?

if you are using the DJI remote v1, then no, you can use the Vista as your radio receiver, just connect the SBUS pad on the Vista to your FC, and configure it in Betaflight. See instructions here: https://oscarliang.com/dji-fpv-system-setup/#Using-DJI-Remote-Controller

Hi Oscar your information is very good, and very informative, we already modified from analog to Digital, we used Runcam Link, but we ran into some problems after that, the battery dropped to 10 volts (Lipo 4s) after flying for less than 1 minute, can you advise for this trouble ?

I am new to the whole scene and looking into building my first fpv drone and have a question regarding the battery used and the total weight. How much would using a 4S battery impact the total weight of the drone? Would you be able to build a similar 4S quad which is less than 500g, considering sub 500g quads can be flown basically everywhere where as there are some restrictions on drones heavier than 500g where I live. Or could this also be achieved by using a smaller capacity 6S battery than used in the guide?

It’s totally possible to build a 5″ drone that weighs below 500g (including battery), for example the Emax Hawk Apex. Ultimately it just depends on the components you want to use and what kind of performance you want to get out of it.

The weight of a battery does not depend on cell count, but the total watt hour (energy stored in the battery). For example, a 4S 1500mAh battery would weigh similar to a 6S 1000mAh, because they have the same watt hour (= voltage * capacity).

You can totally use a smaller 6S battery with the drone we build in this tutorial, the only downside is shorter flight time. By reducing the weight of the drone, you can get some of the lost flight time back, for example, by using lighter components.

Hi Oscar,

I had recently built a quad using this guide, it was really helpful. For motors I had used Emax Eco 2 2207 1900KV.

It flies pretty well on a 4s, but on 6s it seems to be freaking out sometimes. How could I proceed as, on 4s it feels underpowered..